Laser cutting technology has revolutionized modern manufacturing. However, the quality of the beam in a laser cutting machine plays a crucial role in determining the precision of the cuts. While often overlooked, beam quality significantly affects the performance and accuracy of laser cut machining. This article explores the hidden influence of beam quality on cutting precision, especially in the context of portable cutting laser devices.

I. Understanding Beam Quality

Beam quality refers to the consistency and focus of the laser beam. It determines how well the laser cutting machine can concentrate energy on a specific point. A high-quality beam has minimal divergence and a well-defined focus. This allows for more precise and cleaner cuts.

Moreover, beam quality is measured by a parameter known as the M² factor. A lower M² value indicates better beam quality. High-quality beams have an M² value close to 1, meaning the beam is nearly ideal and capable of producing sharp, accurate cuts.

II. The Role of Beam Quality in Laser Cutting

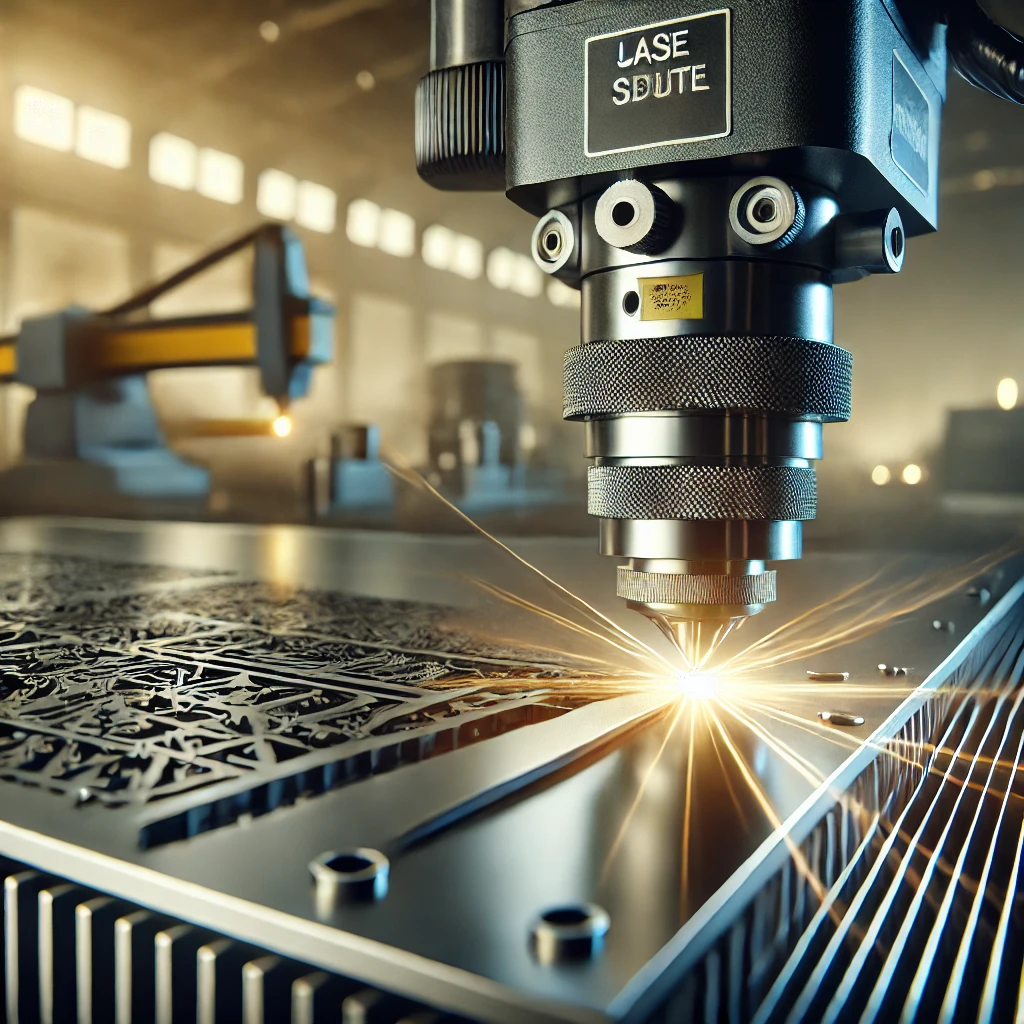

Beam quality directly influences the cutting precision of laser cut machining. A better-quality beam produces narrower kerf widths. This is critical in applications requiring fine details and tight tolerances. When the beam is focused precisely, it cuts through materials with minimal heat distortion, preserving the integrity of the workpiece.

Additionally, beam quality affects the speed of cutting. A superior beam can cut faster while maintaining accuracy. This efficiency is particularly important in high-volume production environments where time and precision are both essential.

III. Impact on Different Materials

The quality of the laser beam also determines how well different materials can be cut. For instance, metals require a high-quality beam to achieve smooth, burr-free edges. In contrast, a lower-quality beam may struggle, resulting in rough edges and increased post-processing.

Furthermore, when using a portable cutting laser on materials like plastics or composites, beam quality becomes even more critical. These materials are prone to heat damage, and a poor-quality beam can cause excessive melting or burning. A high-quality beam minimizes these risks, ensuring clean cuts with minimal waste.

IV. Hidden Challenges with Poor Beam Quality

Poor beam quality can introduce several hidden challenges in laser cut machining. One of the primary issues is increased thermal distortion. A beam with poor focus spreads heat over a larger area, causing warping or discoloration. This not only affects the visual appeal but also the structural integrity of the material.

Moreover, inconsistent beam quality can lead to variability in cut dimensions. This inconsistency is especially problematic in industries where precision is paramount, such as aerospace or medical device manufacturing. The lack of uniformity in the cuts can result in rejected parts and increased production costs.

V. The Importance of Maintenance

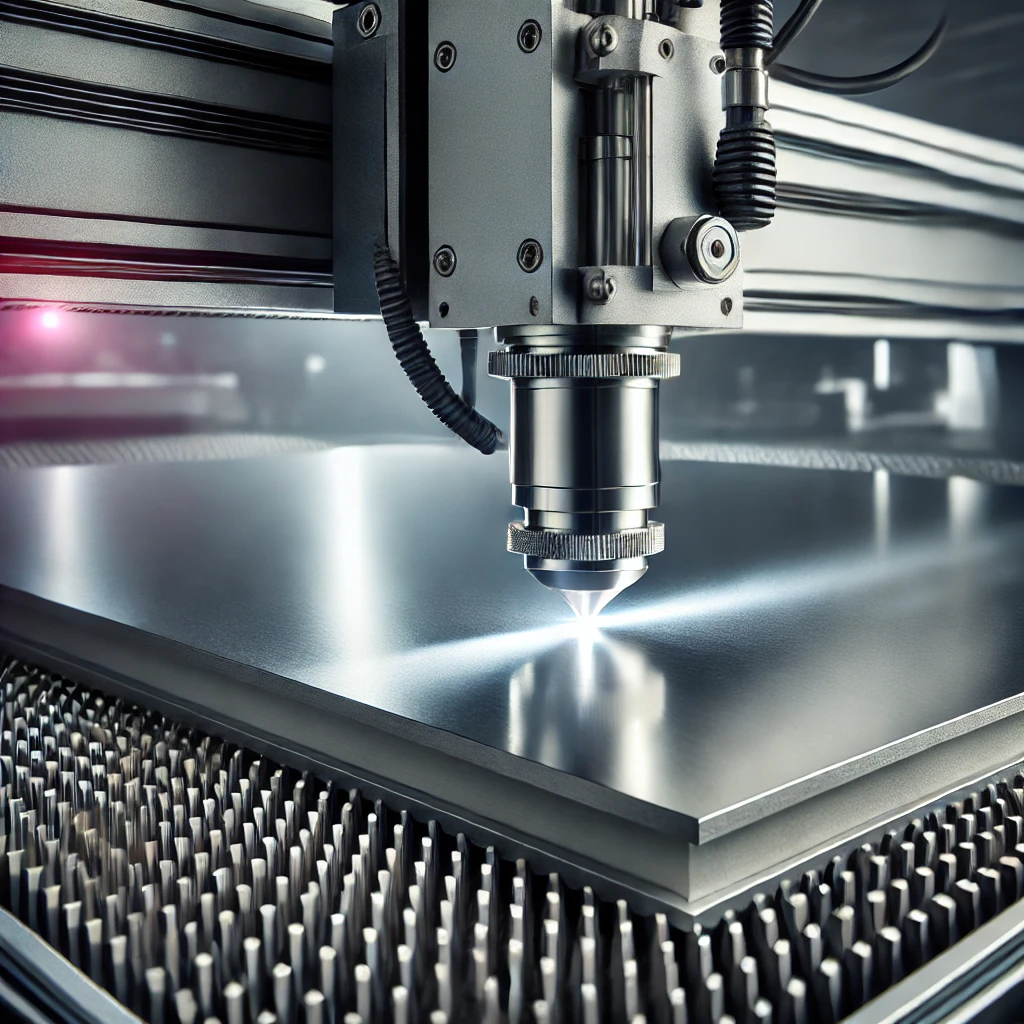

Regular maintenance of laser cutting machines is essential to maintaining optimal beam quality. Over time, components like lenses and mirrors can degrade, affecting the beam’s focus. Cleaning and aligning these components regularly ensures that the beam remains sharp and consistent.

Additionally, operators should monitor the machine’s performance and make adjustments as needed. For portable cutting lasers, which are often used in varying environments, maintaining beam quality can be more challenging. Ensuring the device is well-maintained and calibrated is crucial for achieving precise cuts.

VI. Technological Advancements in Beam Quality

Recent advancements in laser technology have focused on improving beam quality. Modern laser cutting machines feature more sophisticated optics and control systems. These advancements allow for better focus and more consistent beam quality, even at high power levels.

Moreover, the development of adaptive optics has significantly enhanced the precision of laser cut machining. Adaptive optics adjust the beam in real-time, compensating for any distortions or aberrations. This technology ensures that the beam remains focused, resulting in more accurate cuts.

VII. Portable Cutting Laser and Beam Quality

Portable cutting lasers are becoming increasingly popular due to their convenience and flexibility. However, maintaining beam quality in these devices can be challenging. Portable lasers often face varying environmental conditions, which can affect beam focus.

To address this, manufacturers are developing portable lasers with better beam stabilization features. These features ensure that the beam quality remains consistent, even in less controlled environments. As a result, portable cutting lasers can achieve precision similar to their larger counterparts.

VIII. The Future of Beam Quality in Laser Cutting

As laser technology continues to advance, the focus on improving beam quality will likely intensify. Enhanced beam quality will lead to even greater precision in laser cut machining. This improvement will be particularly beneficial in industries that demand high accuracy, such as electronics or microfabrication.

Furthermore, the integration of AI and machine learning into laser cutting machines promises to optimize beam quality further. These technologies can analyze and adjust the beam in real-time, ensuring consistently high performance.

IX. Conclusion

In conclusion, the quality of the laser beam in a laser cutting machine is a critical factor that significantly influences cutting precision. While often considered a technical detail, beam quality has profound effects on the efficiency, accuracy, and overall performance of laser cut machining. This is especially true for portable cutting lasers, where maintaining beam quality is essential for achieving high-precision results. As technology evolves, the importance of beam quality will continue to grow, driving innovations that enhance the capabilities of laser cutting in various applications.