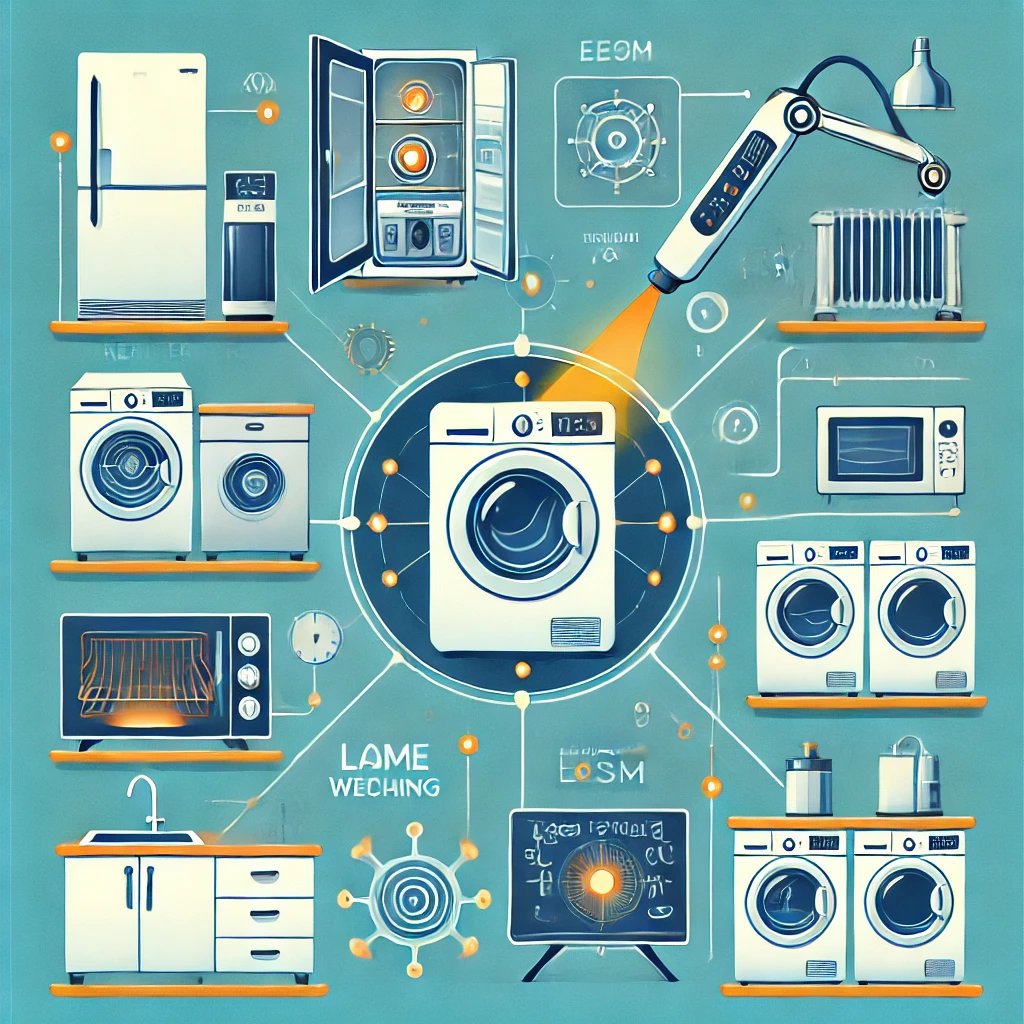

The home appliance industry, characterized by its demand for precision, durability, and efficiency, continually adopts innovative manufacturing techniques to enhance product quality and production efficiency. One such technique is laser welding, which has emerged as a transformative technology in the manufacturing of home appliances. The use of laser welding machines provides technical support for the production of home appliances. The quality of home appliances has been greatly improved, making people’s lives more convenient in making food. This article explores the applications, advantages, and future potential of laser welding machines in the home appliance industry.

I. The Mechanism of Laser Welding

Laser welding is a process that uses a concentrated laser beam to melt and join materials together. This technique offers precise control over the welding process, resulting in clean, strong, and aesthetically pleasing welds. Laser welding is particularly advantageous for joining metals and thermoplastics, making it suitable for various components in home appliances.

II. Applications in the Home Appliance Industry

1. Refrigerators and Freezers

Laser welding is used to join the thin metal sheets that form the outer casing and inner liners of refrigerators and freezers. The precise and strong welds ensure the structural integrity and thermal efficiency of these appliances, contributing to their overall performance and longevity.

2. Washing Machines and Dryers

The drum and other metal components of washing machines and dryers benefit from laser welding. This technique provides seamless and robust joints that can withstand the high-speed rotations and vibrations during operation, ensuring durability and reliability.

3. Microwave Ovens

In microwave ovens, laser welding is employed to join the metal parts of the oven cavity and the external casing. The precise welds help maintain the structural integrity and safety of the microwave, as well as its ability to contain electromagnetic radiation effectively.

4. Dishwashers

The internal and external metal components of dishwashers, including racks, spray arms, and housings, are often joined using laser welding. The strength and precision of laser welds enhance the durability and performance of these components, ensuring long-term reliability.

5. Air Conditioners and HVAC Systems

Laser welding is used in the manufacturing of air conditioners and HVAC systems to join the metal components of heat exchangers, coils, and casings. The precise and strong welds help improve the efficiency and lifespan of these systems.

III. Benefits of Laser Welding in Home Appliance Manufacturing

1. Precision and Accuracy

Laser welding offers unparalleled precision, creating clean and accurate welds. This reduces the need for post-weld processing and ensures high-quality joints, essential for the performance and appearance of home appliances.

2. Strength and Durability

Welds created by laser welding machines are exceptionally strong and durable, providing long-lasting performance. This is crucial for home appliances that undergo constant use and exposure to various operating conditions.

3. Aesthetic Appeal

The clean and smooth welds produced by laser welding enhance the aesthetic appeal of home appliances, which is important for consumer satisfaction and market competitiveness.

4. Efficiency and Speed

Laser welding is a fast and efficient process, increasing production speed and reducing manufacturing costs. This enables manufacturers to meet high demand while maintaining quality standards.

5. Minimal Heat Affected Zone (HAZ)

Laser welding generates a minimal heat-affected zone, reducing the risk of material distortion and weakening. This is particularly important for maintaining the properties of thin metal sheets and delicate components used in home appliances.

IV. Challenges and Considerations

While laser welding machines offer numerous benefits, their adoption in the home appliance industry is not without challenges. The initial investment in laser welding technology can be substantial, and skilled operators are required to achieve optimal results. Additionally, integrating laser welding into existing manufacturing workflows may require adjustments and training.

V. Future Prospects

The future of laser welding in the home appliance industry looks promising. As the technology continues to advance, we can expect even greater precision, efficiency, and versatility. Innovations such as automated laser welding systems and enhanced control mechanisms will further improve the applicability and benefits of laser welding in home appliance manufacturing.

VI. Conclusion

Laser welding machines have significantly impacted the home appliance industry, offering a range of benefits from precision and durability to efficiency and aesthetic appeal. As the technology evolves, its role in home appliance manufacturing will likely expand, leading to even more innovative and high-quality products. Embracing laser welding technology allows manufacturers to meet the demands of modern consumers, providing durable, efficient, and visually appealing home appliances that stand the test of time.