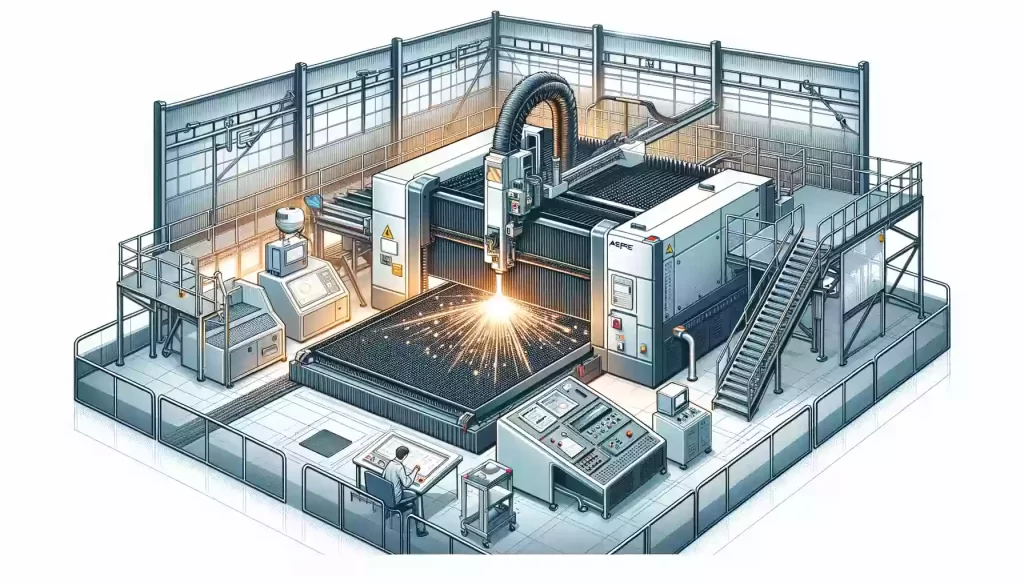

Fiber laser cutter have now become an indispensable processing equipment in the modern sheet metal industry. With the upgrading of the industry and the improvement of processing requirements, fiber laser cutting machines have not only greatly improved their efficiency, but also achieved the ultimate in operation optimization. The following will introduce in detail the specific operation process of the fiber laser cutting machine and the solutions to common faults.

Ⅰ.Operation Steps of Fiber Laser Cutting Machine

1.Determine the processing material:

After determining the material to be processed, fix the sheet metal material flat on the processing machine and ensure the stability of the material placement to avoid jitter during the cutting process, resulting in the cutting accuracy not meeting the requirements.

2.Set cutting parameters:

Operate the console, enter the cutting pattern of the product, the thickness of the cutting material and other parameters, then adjust the cutting head to the appropriate focus position, and check and adjust the center position of the nozzle to ensure cutting accuracy.

3.Start the equipment:

Start the voltage stabilizer and chiller, and set the water temperature and water pressure of the chiller to ensure that the equipment will not overheat during operation. Next, start the laser, then turn on the machine tool and prepare to start the cutting operation.

4.Monitor the cutting process:

During the cutting process, the operator needs to monitor the operation of the fiber laser cutter in real time to ensure that the cutting process proceeds smoothly. Once an abnormality is found, the operation should be suspended immediately, and the fault should be checked and eliminated.

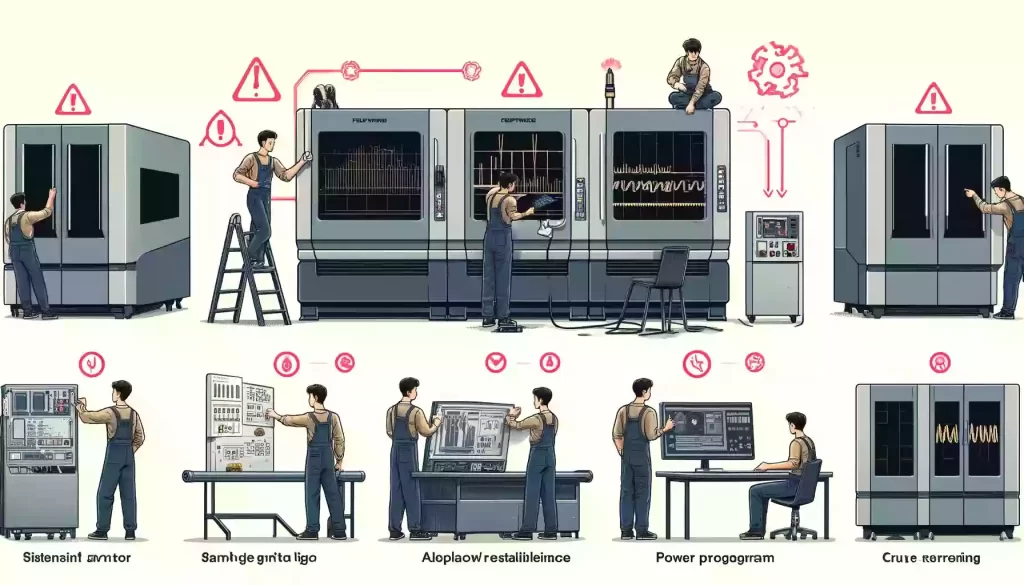

Ⅱ.Common Faults and Solutions

1.No response when the machine is turned on

Is the power fuse burned out: Check and replace the fuse.

The power input normal: Check the power input and ensure that it works properly.

The main power switch damaged: Check and replace the main power switch.

2.No laser output or the laser is very weak

Is the optical path offset: Carefully adjust the optical path to ensure that the laser beam path is correct.

Does the focus of the equipment change: Re-adjust the focal length to ensure that the focus is accurate.

The laser tube damaged or aged: Check and replace damaged or aged laser tubes.

Laser power supply powered: Check the laser power supply circuit to ensure that it is powered normally.

Laser power supply damaged: If the laser power supply is damaged, replace a new laser power supply.

3.There is an error in the processing size or an error in the action

Is the signal line normal: Check and replace the damaged signal line.

The power supply is unstable or there is an interference signal: Install a voltage stabilizer or eliminate the interference signal to ensure stable power supply.

Are the processing parameters set correctly: Check and reset the cutting parameters to ensure their correctness.

Is the processing program written normally: Check the written processing program and modify it until it runs normally.

Ⅲ.Operation Precautions

In the actual operation process, although the above steps seem short, it takes a lot of time to practice and familiarize yourself with every detail in actual operation. The following are some operation precautions:

1.Safety protection:

Be sure to wear appropriate protective equipment during operation, such as protective glasses, protective gloves, etc., to prevent laser radiation and splashes during cutting from causing harm to the operator.

2.Equipment maintenance:

Regularly check the various components of the equipment, including the optical path system, cooling system, laser source, etc., to ensure that the equipment is always in good working condition.

3.Cleaning work:

Regularly clean the fiber laser cutter and optical components to prevent dust and impurities from affecting the cutting effect.

4.Training and assessment:

Operators should receive professional training and pass relevant operation assessments to ensure that they have the ability to operate the fiber laser cutting machine proficiently.

Ⅳ.Advantages of Fiber Laser Cutting Machine

Compared with traditional cutting equipment, fiber laser cutting machine has many advantages:

1.High efficiency:

The fiber laser cutting machine has a fast cutting speed, is suitable for large-scale production, and can greatly improve production efficiency.

2.High precision:

The fiber laser cutting machine has high cutting precision and can process very complex patterns to meet the needs of high-precision processing.

3.Wide applicability:

Fiber laser cutting machines can cut a variety of materials, including metals and non-metallic materials, and have a very wide range of applications.

4.Environmental protection and energy saving:

Fiber laser cutting machines have low energy consumption, less waste gas and waste generated during the cutting process, and less pollution to the environment. They are environmentally friendly and energy-saving cutting equipment.

Final Thoughts

Through the above detailed operation process and solutions to common faults, fiber laser cutting machines can better utilized to improve work efficiency and processing quality, and meet the high standards of the modern sheet metal industry.