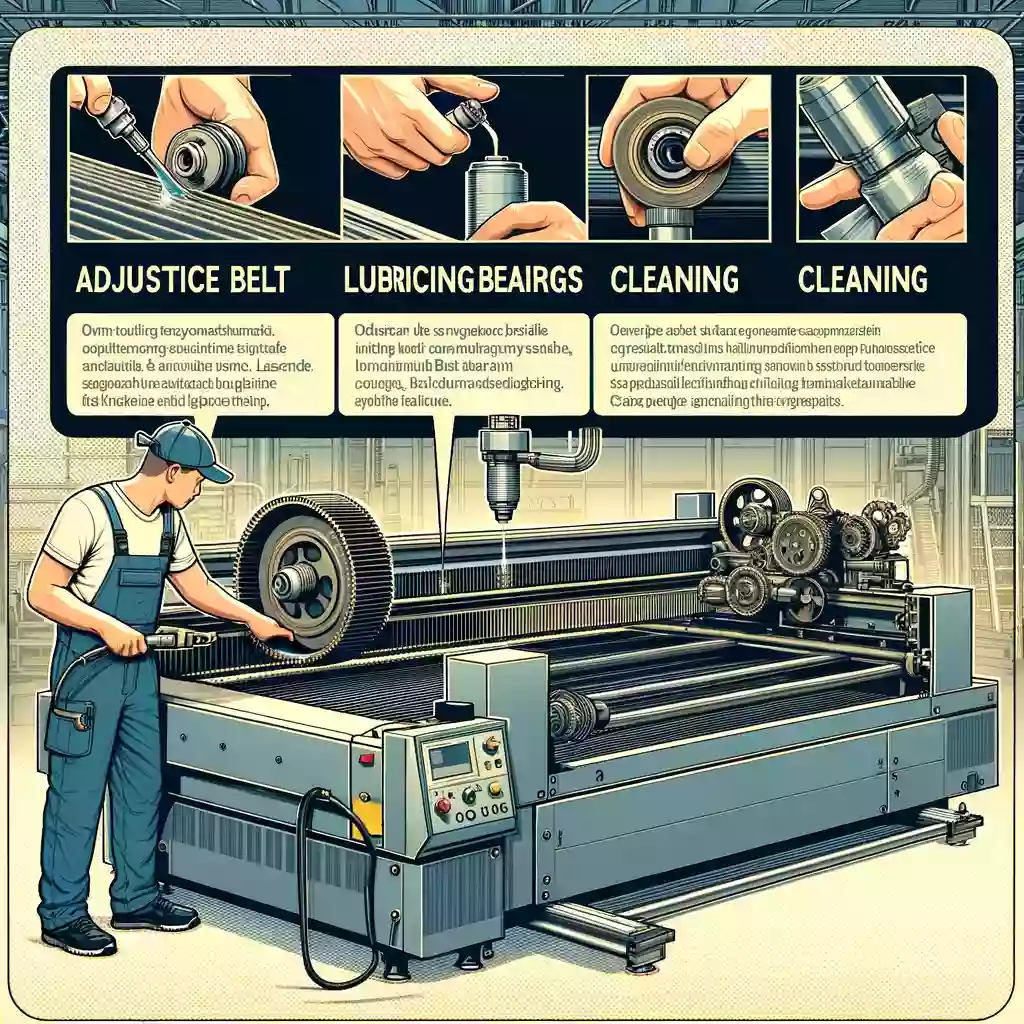

Maintenance of the Laser Cutting Machine Transmission System

The transmission system in the fiber laser cutter contains several synchronous belts. The tightness of the synchronous belt has a direct impact on the working performance of the machine. If the synchronous belt is too loose, the engraved font will appear ghosting. If the synchronous belt is too tight, it will cause the synchronous belt to wear. The following is a detailed guide on the maintenance of the laser cutting machine transmission system:

Ⅰ.Adjust the Tightness of the Synchronous Belt

After using it for a period of time, you need to check and adjust the tensioning screws of the synchronous belt to adjust the synchronous belt to the appropriate tightness. The appropriate tightness can ensure that the engraved text does not appear ghosting, while keeping the operating noise of the wood engraving machine low. If you are not sure how to adjust it, it is recommended to consult the manufacturer’s technicians for professional guidance.

Ⅱ.Bearing Lubrication and Maintenance

The fiber laser cutter uses a large number of bearings. In order to ensure good cutting and engraving effects, some bearings need to be refueled regularly (except oil-containing bearings). The steps are as follows:

The first step is to wipe off the loose soil on the bearing with a clean soft cloth. The second step is to absorb an appropriate amount of engine oil with a needle tube, and then slowly inject it into the bearing with a needle. The third step is to slowly rotate the bearing while filling the oil to ensure that the engine oil fully enters the bearing.

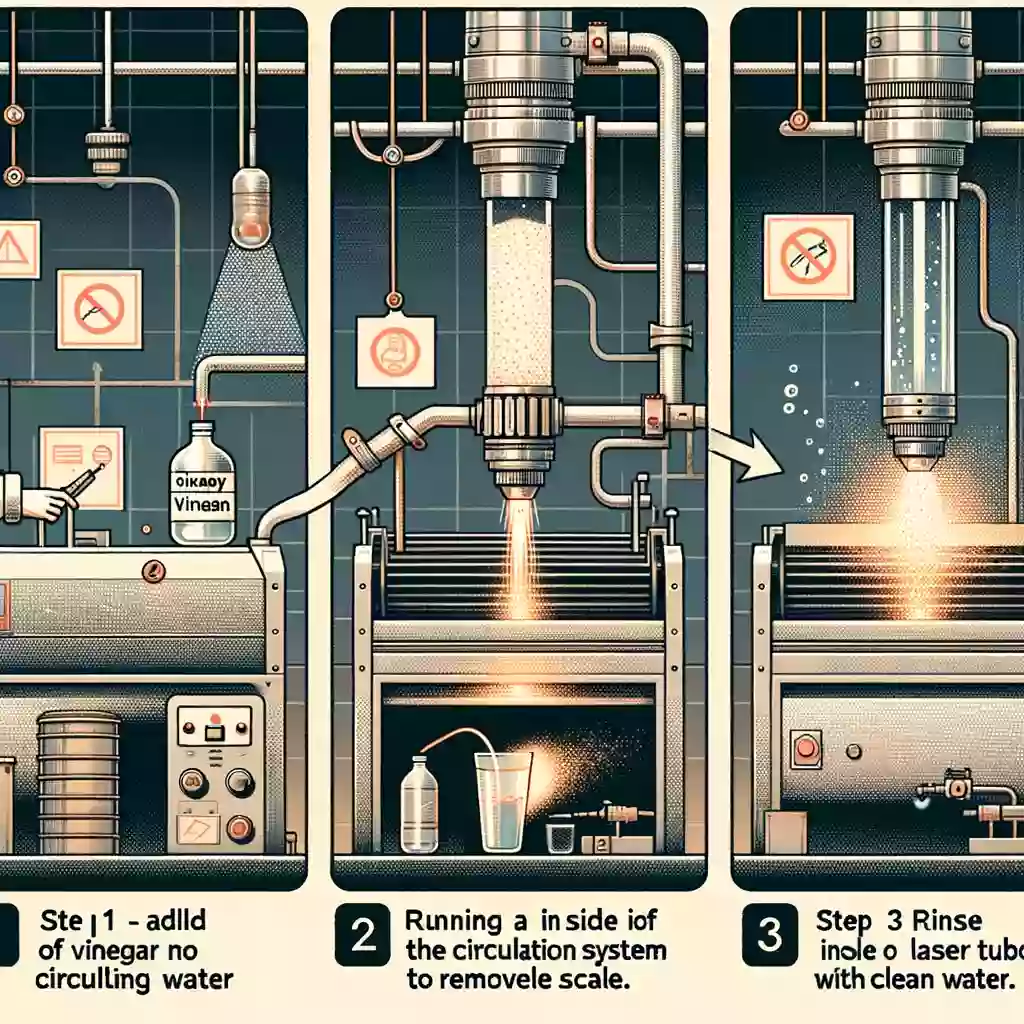

Ⅲ.Laser tube maintenance

The laser tube in the laser engraving machine is cooled by circulating water. After long-term use, some white scale will accumulate in the tube. The cleaning method is as follows: Step 1, add a small amount of vinegar to the circulating water and run the circulation system to remove the scale in the tube. After that, rinse the inside of the laser tube with clean water several times to ensure that there is no residual scale. This can ensure that the laser tube is in the best working condition and extend its service life.

Ⅳ.Lubrication and maintenance of the guide rail

After the laser engraving machine has been used for a period of time, the smoke and dust generated by engraving and cutting will corrode the guide rail. So the guide rail needs to be maintained regularly. The specific steps are as follows:

Step 1, turn off the power of the laser engraving machine. And clean the guide rail with a clean soft cloth.

Step 2, drip an appropriate amount of lubricating oil on the guide rail. And then let the slider roll back and forth on the guide rail to ensure that the lubricating oil enters the inside of the slider. After lubrication is completed, reinstall the guide rail. Be careful not to fix the guide rail first during installation. All fixing nails need to installed and kept level, then the belt and the slider fixed. And finally the dimming is completed.

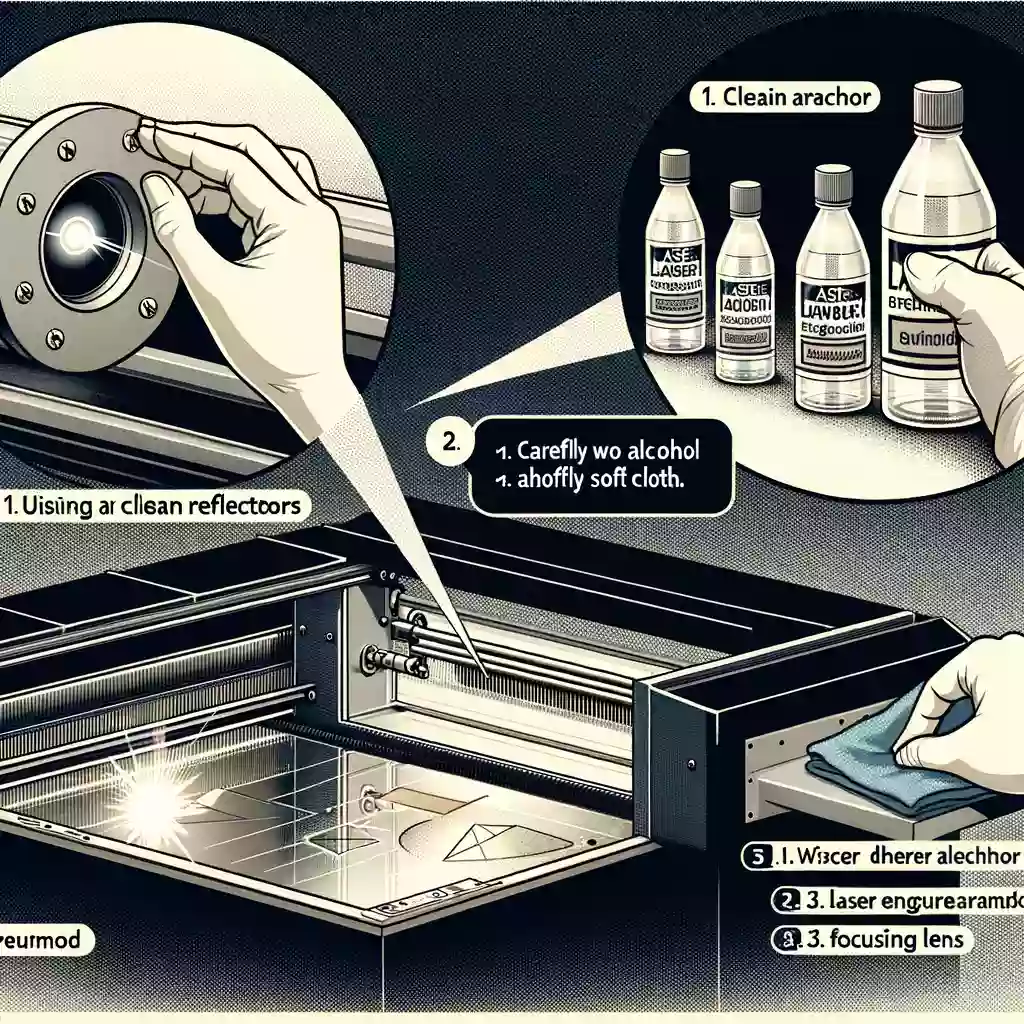

Ⅴ.Cleaning and maintenance of lenses

Wipe the reflector and focusing lens. After using the laser engraving machine and laser cutting machine for a period of time, smoke and dust will adhere to the surface of the lens. These affecting the engraving and cutting depth and accuracy. Generally, cleaning required once a week or so (depending on the frequency of use). The steps are as follows: Use anhydrous alcohol and a clean soft cloth to carefully wipe three reflectors and one focusing lens. Make sure there is no dust and dirt on the surface of the lens to ensure the best transmission and focusing effect of the laser beam.

Final Thoughts

By regularly maintaining and servicing the laser cutting machine, the service life of the equipment can effectively extended . And the processing quality and efficiency can improved. Key maintenance includes adjusting the tightness of the synchronous belt, lubricating the bearings, cleaning the laser tube, lubricating the guide rails, and wiping the lenses. These steps not only ensure the smooth operation of the equipment, but also reduce the failure rate and maintenance costs. For the best results, users should strictly follow the operation manual and maintenance guide for maintenance, or consult professional technicians for advice and support. Through scientific maintenance methods, the laser cutting machine can kept in the best working condition, providing reliable guarantee for production.