Inventory of the Application Process of Laser Engraving Machines in Several Common Materials

As a new processing technology in the 21st century, laser technology has been widely used in all walks of life due to its many characteristics. From daily life to social and urban construction, laser technology plays an important role. Wood engraving machines are already everywhere, and there are many kinds of materials for laser engraving. Today, this blog will take stock of several common materials and their laser engraving technology methods for your reference.

Ⅰ. Acrylic (plexiglass)

Acrylic is particularly widely used in the advertising industry. This material comes in a variety of shapes and sizes, and the cost of using a laser engraving machine is relatively low.

1. Methods for engraving acrylic

Generally, plexiglass is back-engraved, that is, engraved from the front and viewed from the back. It makes the finished product more three-dimensional. When back-engraving, the graphics must be mirrored first. And the engraving speed must be kept fast and the power must be low. Acrylic is easier to cut, and a blowing device should be used when cutting to improve the quality of the cut. When cutting plexiglass over 8mm, a large-size lens should be replaced.

2. Precautions

It should be noted that the operator cannot leave when cutting plexiglass, because flames may be generated during cutting. Therefore, it is very necessary to maintain monitoring and safety measures. In addition, in order to ensure the quality of cutting, it is necessary to clean the lens and the air blowing device regularly to prevent dust and debris from affecting the transmission and cutting effect of the laser beam.

Ⅱ. Wood

Wood is one of the most common materials in laser processing. Light-colored wood such as birch, cherry or maple can be vaporized by the laser well, so it is very suitable for engraving.

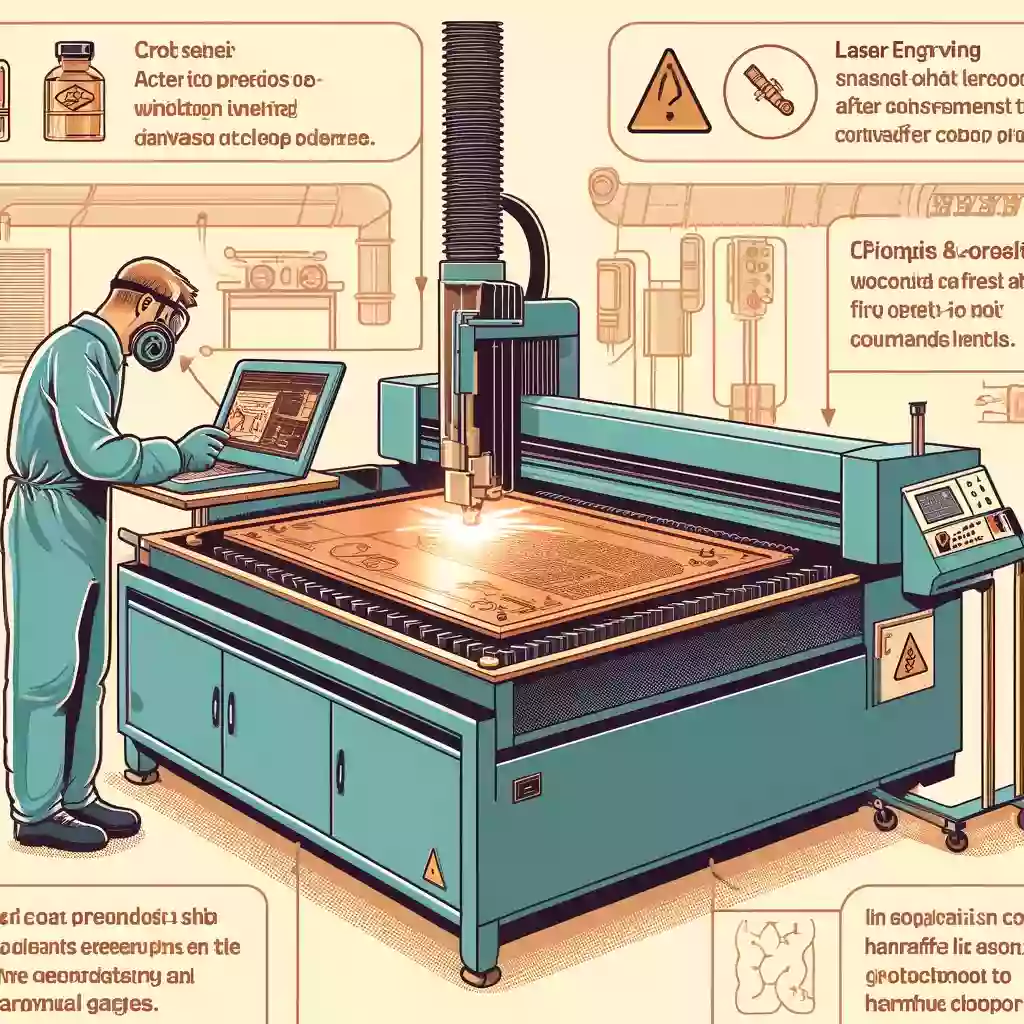

1. Methods for engraving wood

Each type of wood has its own unique characteristics. For example, hardwood is denser and requires greater laser power for engraving or cutting. The depth of laser cutting wood is generally no more than 5mm, which is due to the low power of the laser. If the cutting speed is slowed down, it will cause the wood to burn. In specific operations, you can try to use large-size lenses and adopt repeated cutting methods to achieve better results.

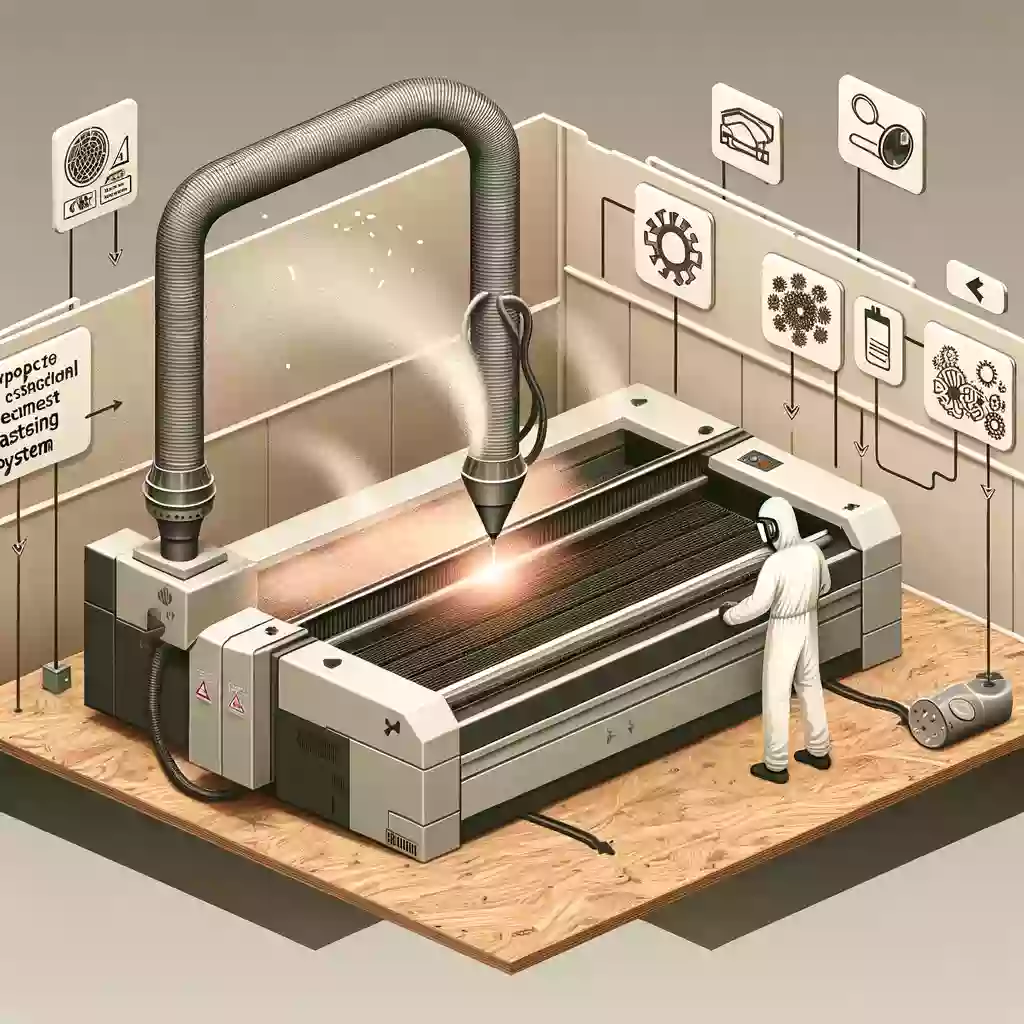

2. Precautions

In addition, smoke and residue will be generated when laser cutting wood, and an appropriate smoke exhaust system needs to be equipped to ensure the cleanliness of the working environment and the health of the operator.

Ⅲ. Density veneer

Density veneer is often used to make sign linings. The material is a high-density board with a thin wood grain on the surface.

1. Methods for engraving density veneer boards

Lasers can be engraved on these materials, but the engraved patterns are uneven in color and black, and usually require coloring. In order to achieve better results, you can use a 0.5mm two-color board for inlay by learning the appropriate design. After engraving, just use a damp cloth to clean the surface of the density board.

2. Precautions

Density veneer boards may produce some tiny debris and dust during the engraving process. The work surface and the internal parts of the wood engraving machine need to be cleaned regularly to maintain the normal operation of the equipment and the stability of the engraving quality.

Ⅳ. Two-color board

Two-color board is a kind of engineering plastic specially used for engraving composed of two or more layers of color composite. The specifications are generally 6001200mm, and there are also a small number of brands with specifications of 600900mm.

1. Methods for engraving two-color boards

The effect of laser engraving on two-color boards is very good, with obvious contrast and clear edges. When cutting two-color plates, be careful not to cut too slowly to avoid cutting through at one time. Cutting should be done in three to four times so that the edges of the cut material are smooth and there are no melting marks. The power should be just right when engraving to avoid melting marks.

2. Precautions

In addition, two-color plates are easily deformed by heat during processing, so pay attention to controlling the power and cutting speed of the laser during operation, and cool it in time to maintain the flatness of the material and the beauty of the engraving effect.

Ⅴ. Galvanized copper plate

Under normal circumstances, copper cannot be engraved by laser.

1. Method for engraving galvanized copper plate

However, there is a material with a special paint film on its surface, and the laser can completely vaporize the paint film on the surface, thereby exposing the underlying copper plate. The manufacturer will polish or perform special treatment on the copper plate before painting to ensure that the exposed area after engraving has sufficient finish and can be preserved for a long time.

2. Precautions

If the copper surface is not treated, a protective film needs to be applied again after using the laser engraving machine to prevent oxidation and surface contamination. In addition, special attention should be paid to safety issues when engraving galvanized copper plates, because harmful gases may be produced under the high temperature of the laser. Therefore, a good ventilation system and personal protective equipment must be equipped to protect the health and safety of operators.

Final Thoughts

Laser engraving technology has become an important part of modern manufacturing due to its high precision and versatility. By mastering the characteristics of different materials and the corresponding laser engraving techniques, the advantages of laser engraving technology can be fully utilized to provide efficient and accurate processing solutions for all walks of life. Whether in advertising production, furniture manufacturing or industrial design, laser engraving shows its unique charm and broad application prospects.