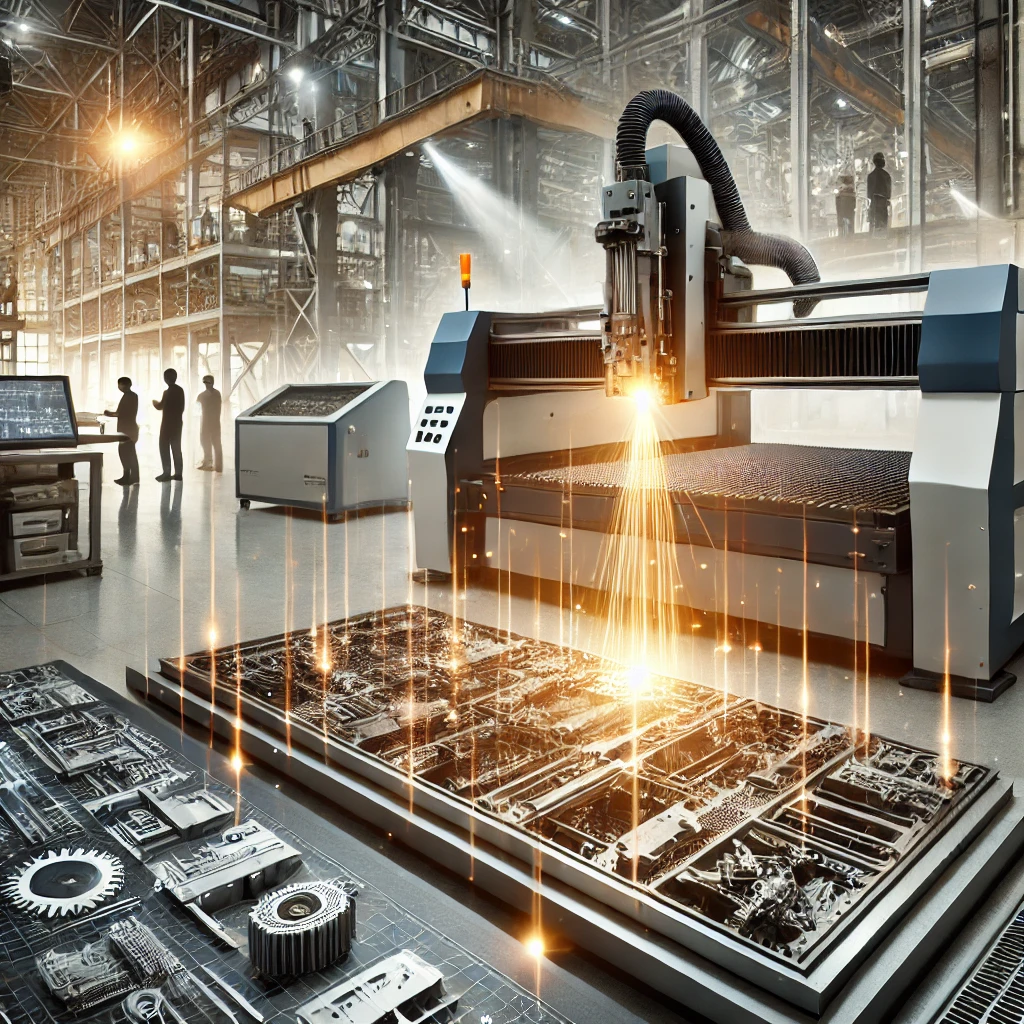

Successful companies constantly seek ways to improve their competitiveness. One effective strategy is leveraging advanced technologies. Laser cutting machines have become essential tools. They offer precision, efficiency, and versatility. This article explores how companies use laser cutting machines to gain a competitive edge.

I. Enhancing Precision and Quality

1. Unparalleled Precision

Laser cutting machines deliver unparalleled precision. They use focused laser beams for cutting. Consequently, they produce clean, accurate cuts. This precision reduces material waste. Additionally, it ensures consistent product quality. High-quality products enhance customer satisfaction. Therefore, companies can build a strong reputation.

2. Handling Intricate Designs

Moreover, laser cutting machines handle intricate designs. They can cut complex shapes with ease. This capability allows for innovative product designs. Unique products attract more customers. As a result, companies can differentiate themselves in the market.

II. Improving Efficiency and Productivity

1. High-Speed Operations

Laser cutting machines operate at high speeds. They complete tasks faster than traditional methods. Consequently, companies can increase production rates. Higher productivity leads to more significant profits. Additionally, quick turnaround times meet customer demands efficiently.

2. Automation and Labor Reduction

Furthermore, laser cutting machines require less manual labor. They automate many cutting processes. This automation reduces labor costs. It also minimizes human errors. Consequently, companies can achieve better consistency. Reduced labor costs improve overall profitability.

III. Expanding Material Capabilities

1. Versatility in Material Handling

Laser cutting machines work with various materials. They can cut metals, plastics, wood, and more. This versatility allows companies to diversify their product offerings. Consequently, they can enter new markets. Diversification reduces business risks. It also opens up additional revenue streams.

2. Optimizing Material Utilization

Moreover, laser cutting machines enable precise material usage. They optimize material utilization, reducing waste. Lower waste translates to cost savings. These savings can be reinvested into the business. Therefore, companies can continually innovate and grow.

IV. Enhancing Customization and Flexibility

1. Meeting Customer Demands

Customization is crucial in today’s market. Customers demand personalized products. Laser cutting machines facilitate customization. They allow for precise modifications. Companies can quickly adjust designs to meet customer needs. This flexibility enhances customer satisfaction.

2. Efficient Small-Batch Production

Additionally, laser cutting machines support small-batch production. They can efficiently handle limited runs. This capability is ideal for prototyping and custom orders. Companies can test new products without significant investments. Consequently, they can respond swiftly to market trends.

V. Reducing Production Costs

1. Minimizing Waste and Labor Costs

Laser cutting machines reduce overall production costs. They minimize material waste and labor expenses. Additionally, they require less maintenance than traditional machines. These factors contribute to lower operational costs. Companies can offer competitive pricing. Therefore, they attract price-sensitive customers.

2. Increasing Profit Margins

Moreover, reduced production costs increase profit margins. Higher margins provide financial stability. Companies can invest in other growth areas. For example, they can enhance marketing efforts. Consequently, they can strengthen their market position.

VI. Boosting Innovation and Creativity

1. Creative Possibilities

Innovation drives business success. Laser cutting machines enable creative possibilities. They handle complex and detailed designs. Companies can experiment with new concepts. This experimentation leads to innovative products. Unique offerings attract customers and boost sales.

2. Streamlining Prototyping

Furthermore, laser cutting machines streamline the prototyping process. Rapid prototyping accelerates product development. Companies can bring new products to market faster. Quick launches capitalize on market opportunities. Therefore, companies stay ahead of competitors.

VII. Improving Environmental Sustainability

1. Reducing Environmental Impact

Environmental sustainability is increasingly important. Laser cutting machines contribute to green initiatives. They produce less waste than traditional methods. Additionally, they use energy efficiently. Reduced waste and energy use lower the environmental impact.

2. Appealing to Eco-Conscious Consumers

Moreover, sustainability appeals to eco-conscious consumers. Companies can market their green practices. This strategy attracts environmentally aware customers. Consequently, it enhances the company’s brand image. Therefore, sustainability efforts can drive sales and customer loyalty.

VIII. Strengthening Competitive Advantage

1. Leveraging Technology for an Edge

In conclusion, successful companies leverage laser cutting machines effectively. These machines enhance precision and quality. They improve efficiency and productivity. Additionally, they expand material capabilities. Laser cutting machines also enable customization and flexibility. They reduce production costs and boost innovation. Furthermore, they contribute to environmental sustainability.

2. Gaining a Competitive Edge

By adopting laser cutting technology, companies gain a competitive edge. They produce high-quality, customized products efficiently. They reduce costs and innovate continually. Moreover, they appeal to eco-conscious consumers. These advantages strengthen their market position.

3. Strategic Investment for Success

Understanding and utilizing laser cutting technology is crucial. Companies that do so can enhance their competitiveness significantly. Therefore, investing in laser cutting machines is a strategic move. It helps companies thrive in a competitive business environment.

IX. Conclusion

Successful companies utilize laser cutting machines to enhance their competitiveness through various strategic applications. By achieving unparalleled precision, improving efficiency, expanding material capabilities, and enhancing customization, these companies set themselves apart in the market. Additionally, reducing production costs, boosting innovation, and committing to environmental sustainability contribute to their overall success. Thus, leveraging laser cutting technology is a critical factor in maintaining and improving competitive advantage in today’s dynamic business landscape.