In the world of woodworking, the introduction of laser technology has revolutionized how artisans and manufacturers approach the cutting of wood. Traditional methods, such as mechanical sawing, have long been the standard for shaping and crafting wood products. However, the advent of laser wood cutters has brought precision and efficiency to new heights. This article explores the differences between these two cutting techniques, focusing on aspects such as precision, speed, and application diversity.

Precision in Cutting

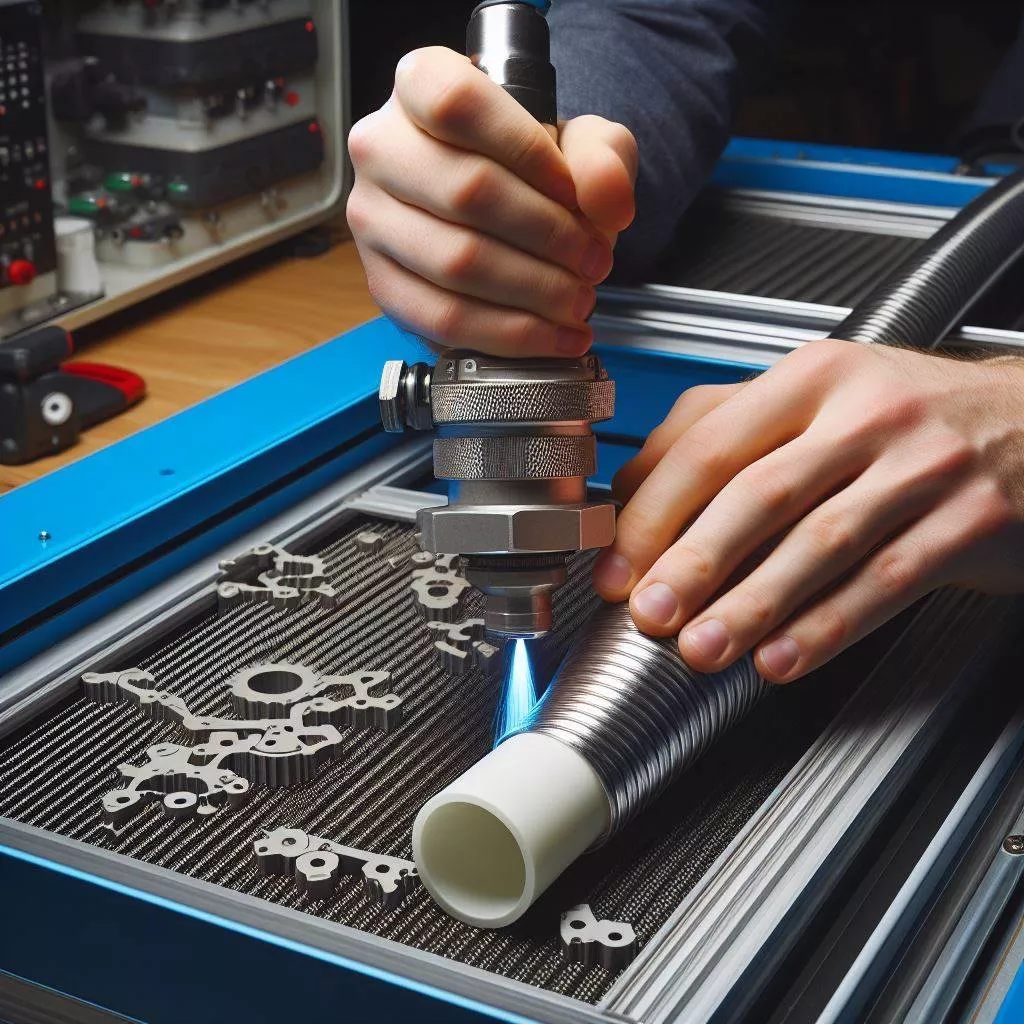

One of the most significant advantages of using a laser wood cutter is the precision it offers. Lasers can produce extremely accurate cuts and intricate details that are challenging to achieve with traditional mechanical saws. The precision of a laser is particularly beneficial when creating complex laser cut designs in wood. Mechanical methods, while effective for straight and simple cuts, often fall short when it comes to intricate patterns and delicate work.

Speed and Efficiency

When it comes to the speed of operation, laser cutters excel significantly over traditional methods. A laser can swiftly move across the surface of the wood, cutting at speeds that mechanical saws cannot match. This efficiency is especially noticeable in projects requiring repetitive patterns or large batches of items. For businesses, this means a faster turnaround from design to final product, which can be crucial for meeting market demands.

Material Handling and Versatility

Wood for laser cutters generally requires less preparation compared to wood prepared for mechanical cutting. Lasers can cut through various types of wood without the need for multiple saw blades or adjustments. This versatility makes a wooden laser cutter an invaluable tool for projects that involve different wood types and densities. In contrast, traditional cutting methods might require different tools or blades to handle various materials, adding time and cost to the project.

Safety and Cleanliness

Safety is another area where laser cutting of wood shows advantages. The contactless nature of laser cutting reduces the risk of accidents typically associated with the physical contact of blades in traditional cutting. Furthermore, laser cutting minimizes wood waste and sawdust, which not only makes the process cleaner but also reduces the cleanup time after operations.

How to Laser Cut Wood

Learning how to laser cut wood involves understanding both the capabilities of the machine and the properties of the wood. Operators must adjust settings like power, speed, and focus depending on the thickness and type of the wood. This level of control allows for precise adjustments that enhance the quality of the final product.

Cost Considerations

While the initial investment in a laser cutting machine might be higher than that for traditional mechanical saws, the long-term benefits often justify the cost. Lasercut wood products typically have cleaner edges and require less finishing work, reducing overall production costs. Additionally, the ability to quickly switch between designs and make adjustments on the fly can lead to significant savings in both time and materials.

Conclusion

The decision between using a laser wood cutter and traditional mechanical methods largely depends on the specific needs of the project. For tasks requiring high precision, complex patterns, and efficiency, a laser cutter is undoubtedly superior. However, for more straightforward cutting tasks, traditional methods might still hold their ground. As technology advances, the capabilities of laser cutters continue to expand, making them an increasingly attractive option for woodworkers looking to push the boundaries of their craft.