Traditional kitchenware processing equipment uses CNC punching machines. And then completes the final shape with processes such as polishing, shearing and bending. This kind of processing efficiency is relatively low. And the mold making time is relatively long and the cost is relatively high. Fiber laser cutter are produced under the premise of the urgent needs of this manufacturer. The development of lasers in our country is very rapid. Metal laser cutting machines can be directly used for mold-free production of various types of kitchenware. It has long-term significance for the kitchenware processing industry. This blog will explore the specific applications and advantages of laser cutting machines for stainless steel kitchenware.

Ⅰ. Basic Principles of Laser Cutting Machine

Laser cutting uses a high-energy laser beam to irradiate the metal surface, melt or vaporize the metal through local high temperature. And it blow away the melt through high-pressure gas to achieve cutting purposes. This cutting method has the characteristics of non-contact, small thermal impact, and smooth incision. It is especially suitable for materials such as stainless steel that require high cutting quality.

Ⅱ. Application of Laser Cutting Machine in the Production of Stainless Steel Kitchenware

1.Structure is stable and reliable.

The structural rigidity complies with industrial machine tool standards. And it has high precision, completely eliminating stress generated during welding and processing. The bed adopts a honeycomb welded structure to ensure that the huge thrust generated by the instantaneous acceleration. Deceleration of the large inertia motor is evenly distributed to all positions of the machine tool. This greatly reducing the vibration of the machine tool.

2.Cutting complex shapes

Stainless steel kitchenware often needs to be cut into various complex shapes, such as pot bottoms, pot lids, knives and other complex contours that are difficult to achieve with traditional cutting methods. The fiber laser cutter can accurately cut any shape in the design drawing through computer control, which not only improves production efficiency, but also ensures cutting accuracy.

3.High-precision machining

The cutting accuracy of the laser cutting machine is as high as 0.1 mm, which can meet the high requirements of stainless steel kitchenware in terms of appearance and function. For example, the sharpness and smoothness of stainless steel knives directly affect its use effect. Laser cutting technology can ensure the uniformity and smoothness of the blade, making the product more competitive in the market.

4.Improved material utilization

Traditional cutting methods easily cause material waste, but laser cutting machines can maximize the use of materials and reduce the generation of leftover materials by optimizing layout. For example, when cutting a stainless steel pot bottom, the laser cutting machine can accurately layout according to the size of the pot bottom, minimizing material waste and thus reducing production costs.

5.Application of automated production lines

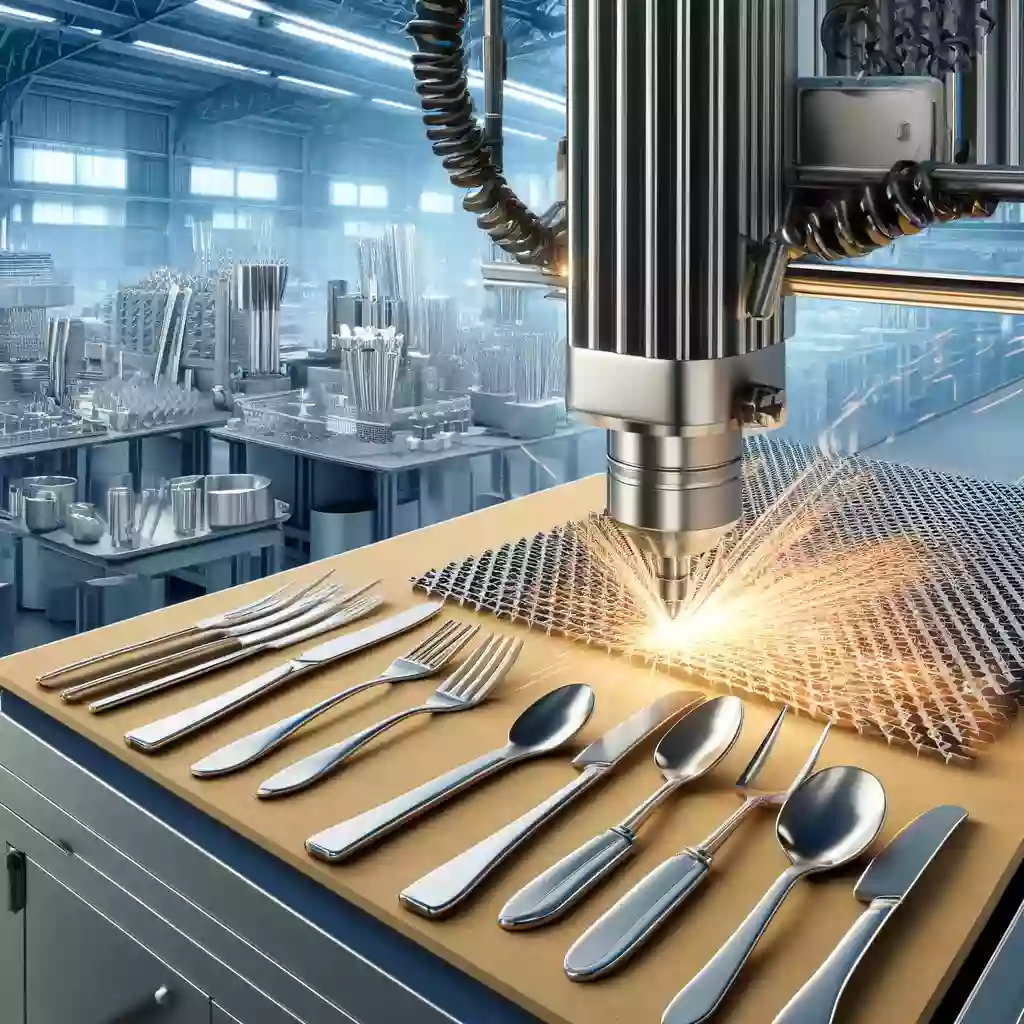

Laser cutting machines can be seamlessly connected with automated production lines to achieve mass production of stainless steel kitchenware. For example, on an automated production line, everything from the loading, cutting, and transportation of stainless steel plates to the off-line of the final product can be completed through computer control and robotic arms, which greatly improves production efficiency and reduces labor costs.

6.Customized production

With the diversification of market demand, customized kitchenware is becoming more and more popular. The laser cutting machine can quickly adjust the cutting parameters according to the customer’s needs and produce kitchenware products that meet the customer’s personalized requirements. For example, if a customer wants to engrave a name or pattern on a knife handle, a laser cutting machine can complete this task quickly and accurately, increasing the added value of the product.

Ⅲ. Cases of Stainless Steel Kitchenware Used in Laser Cutting Machines

1.Stainless steel knives

Stainless steel knives need to cut complex blade shapes and ensure the sharpness and durability of the blade. Laser cutting machines can achieve this goal through high-precision cutting, making the cutting tools more competitive in the market.

2.Stainless steel pots

Stainless steel pots need to be cut into precise shapes for the bottom and lid, and the welded parts must be smooth and flat. The laser cutting machine can cut at high temperatures and remove slag by air blowing to ensure the smoothness of the cutting edge, thus improving the quality of the product.

3.Stainless steel cutlery

Stainless steel tableware such as knives, forks, spoons, etc. need to be cut into complex shapes and the surface finish must be guaranteed. The laser cutting machine can avoid material deformation through non-contact cutting, ensuring the appearance and performance of the tableware.

Ⅳ. Final Thoughts

The application of laser cutting machines in the production of stainless steel kitchenware not only improves production efficiency and product quality, but also reduces production costs and meets the needs of market diversification and customization. As laser cutting technology continues to develop and mature, its application prospects in the field of stainless steel kitchenware will be broader. In the future, laser cutting machines will surely become the main equipment for the production of stainless steel kitchenware, driving the entire industry to develop in the direction of intelligence and automation.