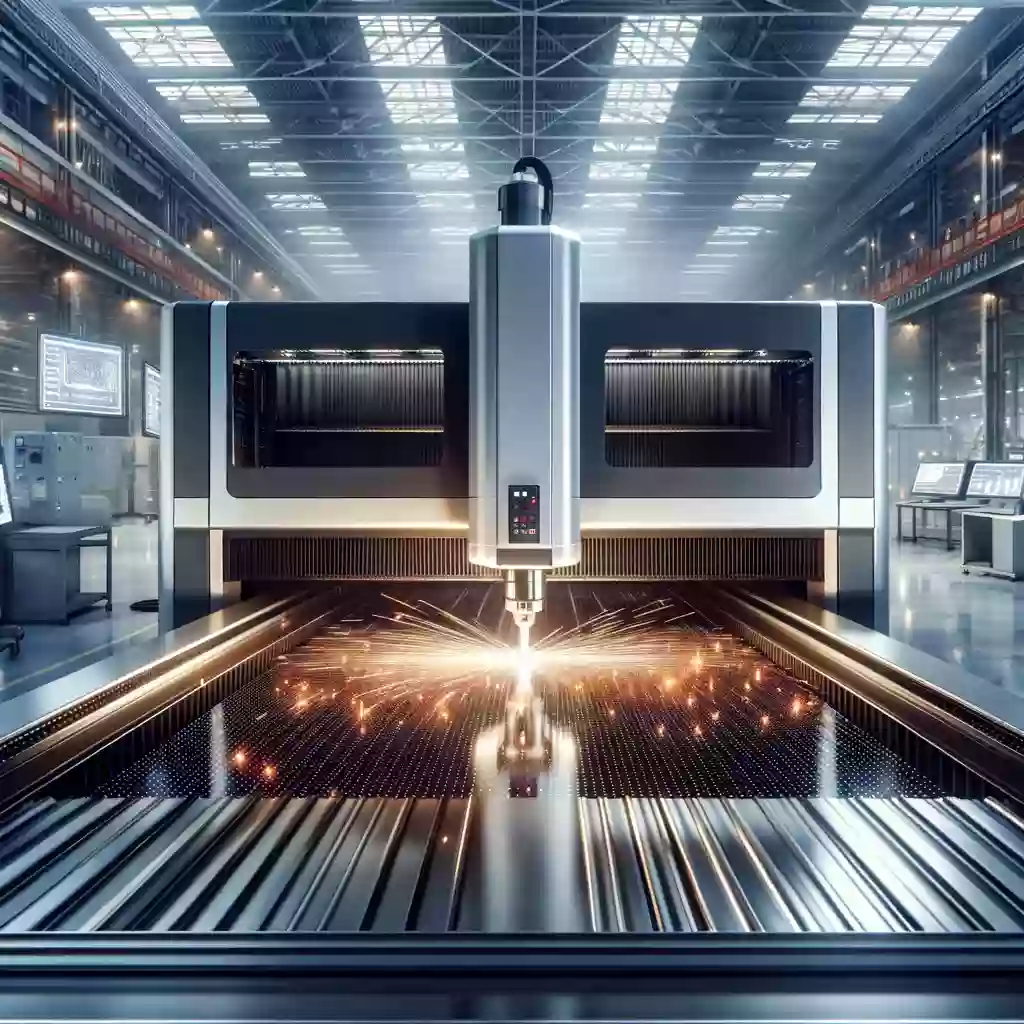

In modern manufacturing, fiber laser cutters have quickly become an indispensable tool in various industries with their unique advantages and excellent performance. From automotive manufacturing to aerospace, from precision instruments to everyday consumer goods, fiber laser cutting machines are used everywhere. Its high efficiency, high precision, high speed and low maintenance costs make this technology stand out in a highly competitive market. This article will discuss the main advantages of fiber laser cutting machine in detail and look forward to its future development direction.

Ⅰ.Advantages of Fiber Laser Cutting Machine

Fiber laser cutters have been widely used in recent years. And their obvious advantages make them stand out in various industries.

1. High performance:

Fiber laser cutting machines use fiber lasers, which have extremely high wall-plug efficiency. The wall-plug efficiency of conventional CO2 lasers is about 10-15%. While the wall-plug efficiency of fiber lasers can reach more than 30%. This means that the fiber laser consumes less energy and saves energy for the same power output.

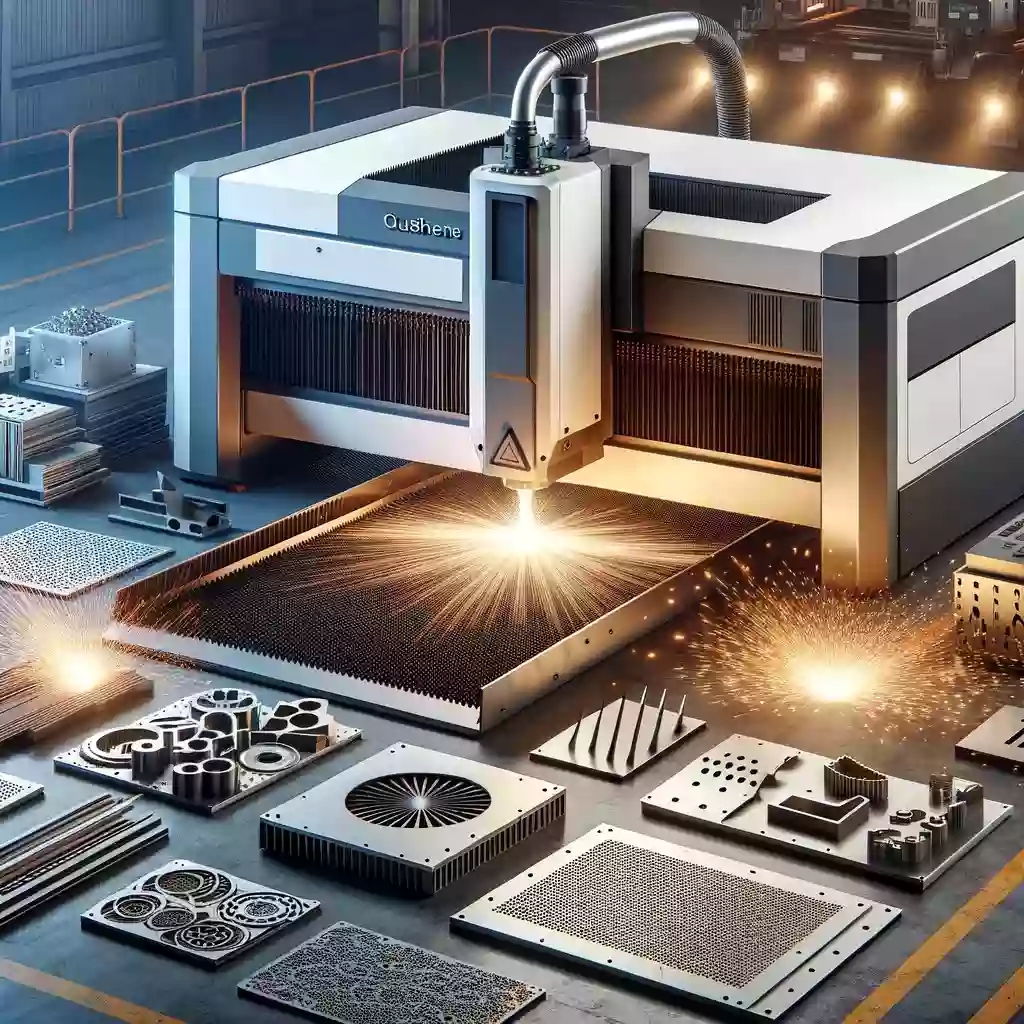

2. High precision:

Fiber laser cutting machines and wood engraving machines can achieve extremely high cutting accuracy. The extremely small diameter of the cutting head and the good quality of the beam make the cutting lines very fine and the edges smooth, without the need for post-processing. For the precision manufacturing industry with strict requirements, the high-precision cutting ability of the fiber laser cutting machine is particularly important. Such as aerospace, electronic appliances, etc.

3. High speed:

The cutting speed of fiber laser cutting machines is much faster than traditional cutting methods. For example, when cutting thin metal sheets, the cutting speed can reach tens of meters per minute. It greatly improves production efficiency. For large-scale manufacturers, the high speed of fiber laser cutting machines means higher production capacity and lower costs.

4. Low maintenance costs:

The structure of the fiber laser cutting machine is relatively simple. It mainly composed of a fiber laser and a motion system. Since fiber lasers do not have a complex lens structure inside, they do not require frequent maintenance and adjustments. Compared with traditional laser cutting machines, its maintenance costs are greatly reduced. And the stability and reliability of the equipment are higher.

5. Versatility:

The fiber laser cutting machine can not only cut metal materials, but also some non-metallic materials, such as plastics. This versatility makes it more versatile in different industries, meeting the needs of a wide range of material processing.

Ⅱ.Development Direction of Fiber Laser Cutting Machine

The development of fiber laser cutting machine is not only limited to the current advantages, but also constantly exploring new technologies and application fields to further improve its performance and application range.

1. Increase the power of the laser:

With the development of science and technology, the power of fiber lasers is constantly increasing. The advent of high-power lasers has made it possible for fiber laser cutters to cut thicker materials, expanding their range of applications. For example, fiber lasers in the kilowatt or even 10,000-watt range are already on the market today and can handle more complex and demanding cutting needs.

2. Intelligent control system:

The control system of the fiber laser cutting machine is developing in the direction of intelligence. By introducing artificial intelligence and machine learning technology, cutting machines can achieve automated production and improve production efficiency and product quality. For example, by monitoring the parameters in the cutting process in real time, the system can automatically adjust the cutting parameters to ensure the best cutting results.

3. Multi-axis linkage technology:

The traditional laser cutting machine is mainly two-dimensional cutting, and the introduction of multi-axis linkage technology makes the fiber laser cutting machine can perform three-dimensional cutting. This is important for the machining of complex shapes, such as in automotive engineering and aerospace, where multi-axis technology enables more complex and delicate cuts.

4. Green and environmental protection:

With the improvement of environmental protection requirements, the development of fiber laser cutting machine also pays more attention to green environmental protection. The new fiber lasers have a higher energy efficiency ratio and reduce energy consumption. At the same time, by optimizing the cutting process, the generation of waste can be reduced and environmental pollution can be reduced.

5. Multi-material composite cutting:

The fiber laser cutting machine of the future will not be limited to the cutting of a single material, but will be able to perform multi-material composite cutting. For example, on the same workpiece, there are both metal parts and non-metal parts, and the fiber laser cutting machine can complete the cutting of all parts in one operation, improving processing efficiency.

Final Thoughts

Fiber laser cutting machines occupy an important position in the manufacturing industry with their high efficiency, high precision, high speed, low maintenance cost and versatility. With the continuous progress of technology and the expansion of application fields, the development prospect of fiber laser cutting machine is very broad. In the future, by increasing the laser power, introducing intelligent control system, multi-axis linkage technology and focusing on green environmental protection, the fiber laser cutting machine will further improve its performance and application range, and bring more convenience and benefits to the production and manufacturing of various industries.