Laser cutting machines have transformed various industries, and toy manufacturing is no exception. Their precision, efficiency, and versatility make them ideal for creating detailed and intricate designs in toys. This article explores how laser cutting machines are applied in the toy industry and their significant impact on toy production.

I. Precision and Accuracy in Toy Manufacturing

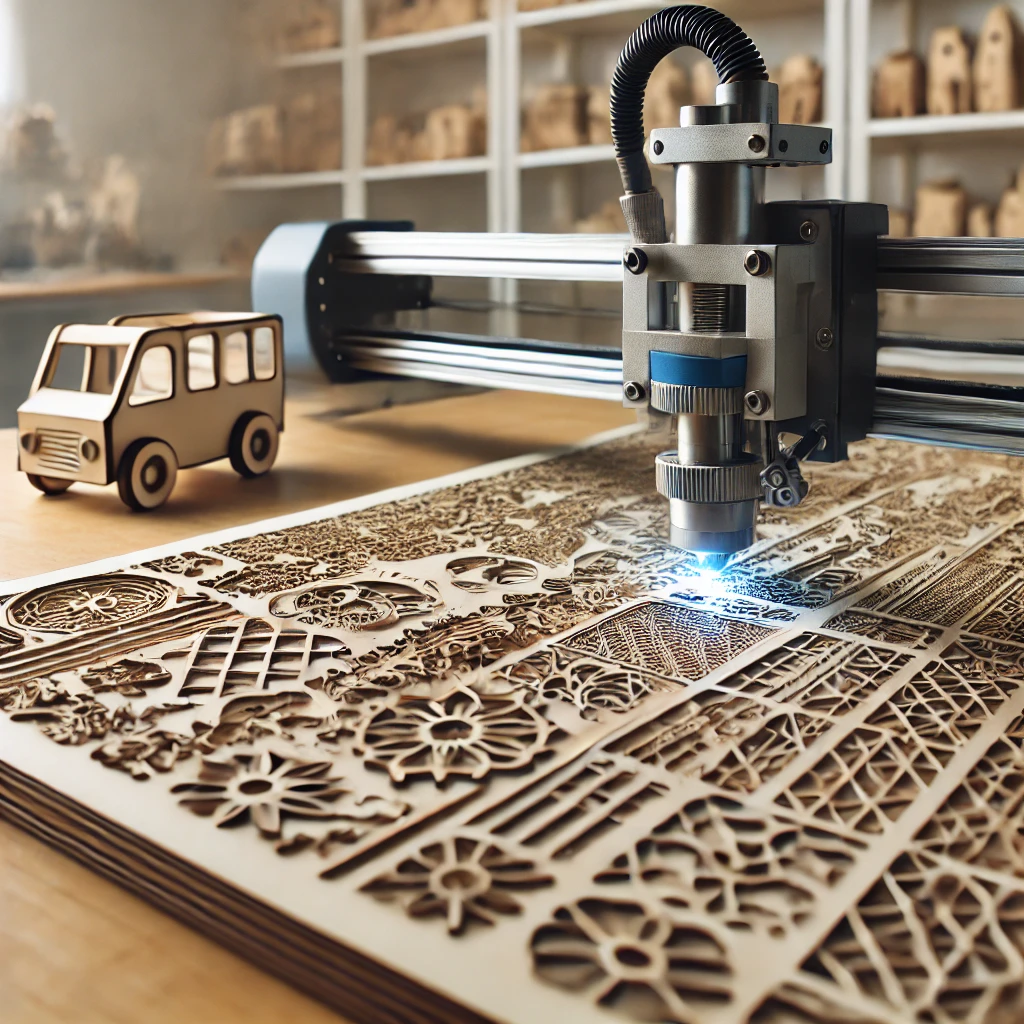

Toy manufacturing requires a high level of precision and accuracy. Laser cutting machines offer the exactness needed to create intricate designs and shapes. Whether it’s cutting small parts for assembly or engraving detailed patterns, laser cutting machines ensure that every piece is made to exact specifications. This precision is particularly important in producing toys that require tight tolerances and complex components.

II. Versatility in Materials

Laser cutting machines are versatile and can work with various materials used in toy manufacturing. These materials include wood, plastic, acrylic, and even fabric. The ability to cut, engrave, and shape different materials with a single machine makes laser cutting a valuable tool in toy production. Whether producing wooden puzzles, plastic action figures, or intricate model kits, laser cutting machines handle all materials with ease and precision.

III. Customization and Flexibility

The toy industry often demands customization to cater to individual preferences. Laser cutting machines excel in providing this flexibility. They can be easily programmed to create custom designs, allowing manufacturers to offer personalized toys. Whether it’s engraving a child’s name on a toy or producing custom-shaped pieces, laser cutting machines enable manufacturers to meet diverse customer needs. This customization also extends to limited edition toys, where unique designs are required.

IV. Speed and Efficiency in Production

In toy manufacturing, speed and efficiency are crucial to meeting production deadlines. Laser cutting machines are known for their rapid processing capabilities. They can cut and engrave materials much faster than traditional methods, significantly reducing production time. This speed is particularly beneficial in mass production, where thousands of toy parts must be manufactured daily. By using laser cutting machines, manufacturers can increase output while maintaining high-quality standards.

V. Enhancing Aesthetic Appeal

The aesthetic appeal of toys is essential for attracting customers. Laser cutting machines allow manufacturers to create intricate designs and patterns that enhance the visual appeal of toys. From detailed engravings on wooden toys to precise cuts in plastic models, a laser cutting machine adds a level of detail that is difficult to achieve with other methods. This capability helps manufacturers produce visually appealing toys that stand out in a competitive market.

VI. Reducing Material Waste

Efficiency in material usage is vital in toy manufacturing, where reducing waste can lead to significant cost savings. Laser cutting machines are highly efficient in material usage, ensuring precise cuts with minimal waste. The precision of the laser allows for close nesting of parts, maximizing the use of raw materials. This reduction in waste is not only cost-effective but also contributes to the sustainability of toy production.

VII. Non-Contact Cutting Process

One of the significant advantages of laser cutting machines in toy manufacturing is the non-contact cutting process. The laser beam cuts without physically touching the material, reducing the risk of contamination or damage. This is particularly important in producing toys that require a high level of cleanliness and precision. The non-contact process ensures that delicate materials are not deformed or damaged during cutting, maintaining the quality of the final product.

VIII. Creating Safety Features

Safety is a top priority in toy manufacturing. Laser cutting machines allow manufacturers to create toys with smooth, precise edges, reducing the risk of sharp corners that could harm children. The ability to control the cutting process with high accuracy ensures that all toy parts are safe for use. Additionally, laser cutting can be used to create safety features such as ventilation holes or rounded edges on toys, further enhancing product safety.

IX. Integration with Automation

The integration of laser cutting machines with automation systems is becoming increasingly common in toy manufacturing. Automation allows for continuous production with minimal human intervention, improving efficiency and consistency. Laser cutting machines can be integrated into automated production lines, where they perform cutting, engraving, and shaping tasks with precision. This integration also enables real-time monitoring and adjustments, ensuring consistent quality throughout the production process.

X. Challenges and Solutions

While laser cutting machines offer numerous benefits, there are challenges associated with their use in toy manufacturing. One challenge is managing the heat generated by the laser, which can affect certain materials. However, advances in laser technology have led to the development of cooling systems and optimized cutting parameters that minimize this risk. Another challenge is ensuring the correct laser settings for different materials, but with proper calibration, these machines can be adjusted to handle various materials effectively.

XI. Future Prospects

The future of laser cutting machines in toy manufacturing looks promising. As technology continues to advance, these machines will become even more precise and versatile. The development of new materials and toy designs will drive further innovation in laser cutting technology. Additionally, as laser cutting machines become more accessible, their use in toy manufacturing will likely expand, leading to more widespread and effective production processes.

XII. Conclusion

Laser cutting machines have revolutionized the toy industry by offering precision, efficiency, and versatility. Their application in cutting, engraving, and shaping toy materials has made them indispensable tools in modern toy manufacturing. As technology continues to evolve, the role of laser cutting machines in toy production will only grow, driving innovation and improving production efficiency. With the right approach, laser cutting machines will continue to play a crucial role in the future of toy manufacturing.