In the modern jewelry manufacturing industry, technological advancements have brought unprecedented changes. Fiber laser cutters, as high-precision mechanical equipment, are becoming essential tools in jewelry making due to their outstanding performance and versatile applications. This article explores the extensive applications of laser cutting machines in the field of jewelry, their advantages, and their impact on future development.

I. Working Principle of Laser Cutting Machines

Fiber laser cutters utilize high-energy laser beams, which are focused through a lens to a very small point, causing the material to rapidly melt or vaporize, thereby achieving precise cutting. This technology is suitable not only for metals like gold, silver, and platinum but also for non-metal materials like diamonds, gemstones, and plastics. Due to its high precision, speed, and efficiency, laser cutting machines have found widespread use in jewelry making.

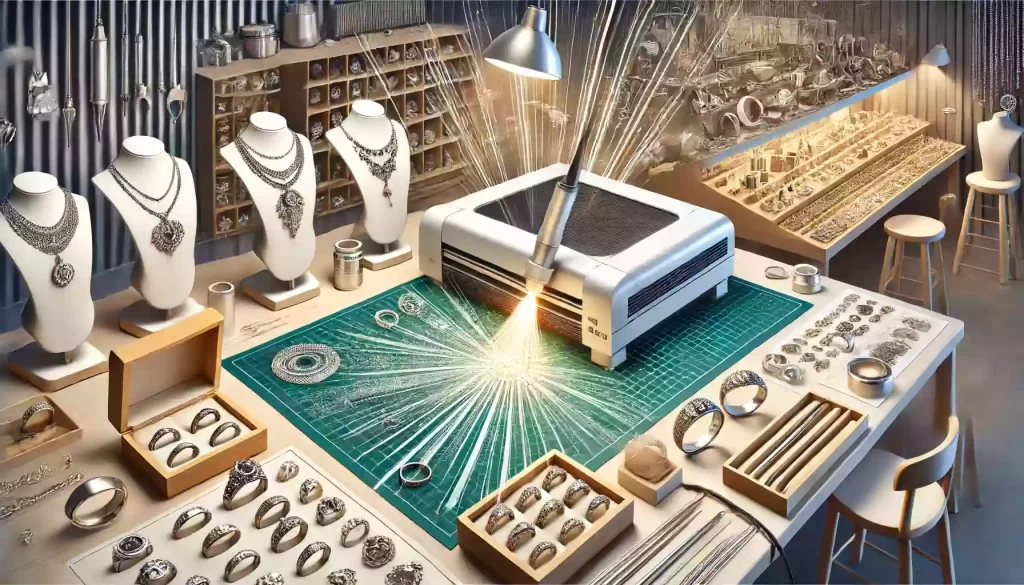

II. Specific Applications of Laser Cutting Machines in Jewelry Making

1.Cutting and Engraving:

Laser cutting machines can perform precise cutting and engraving on both metal and non-metal materials. Traditional cutting methods, such as sawing and manual engraving, are not only inefficient but also prone to errors. Laser cutting machines can complete complex patterns quickly, significantly improving production efficiency and product quality. For instance, intricate ring patterns and engraved designs on bracelets can be efficiently and accurately created using laser cutting machines.

2.Hollow Designs:

Hollow designs in jewelry often require extremely high craftsmanship. Laser cutting machines can easily accomplish these complex designs, ensuring that the patterns are exquisite and detailed while greatly reducing manual operation errors. Hollow earrings, pendants, and other pieces can achieve a highly artistic and three-dimensional effect through laser cutting technology.

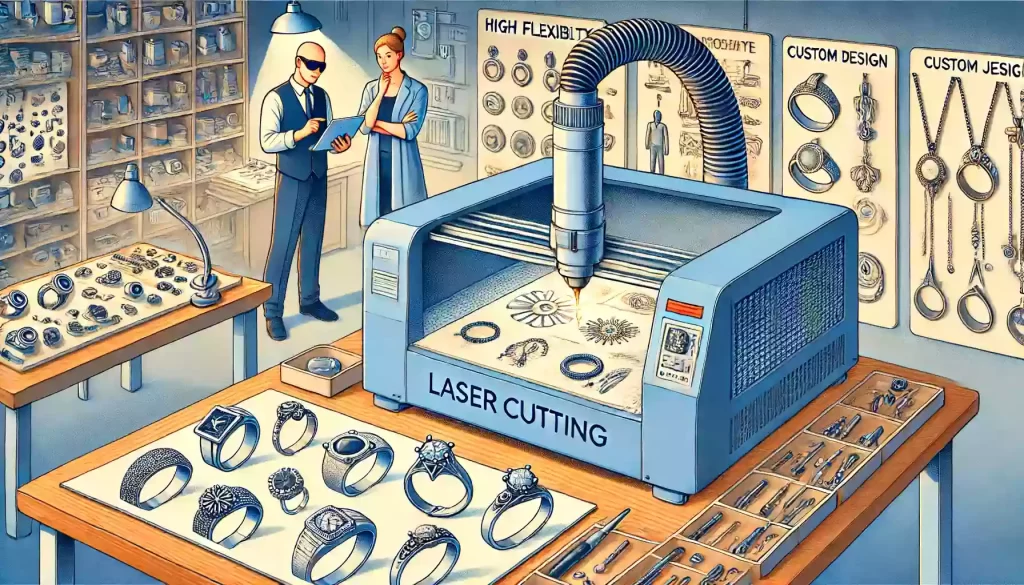

3.Customized Production:

With the increasing demand for personalization, customized jewelry is gaining popularity among consumers. Laser cutting machines can quickly design and cut unique pieces according to customer requirements, such as necklaces and rings with personal insignia. The flexibility and precision of laser technology make customized production more convenient and efficient.

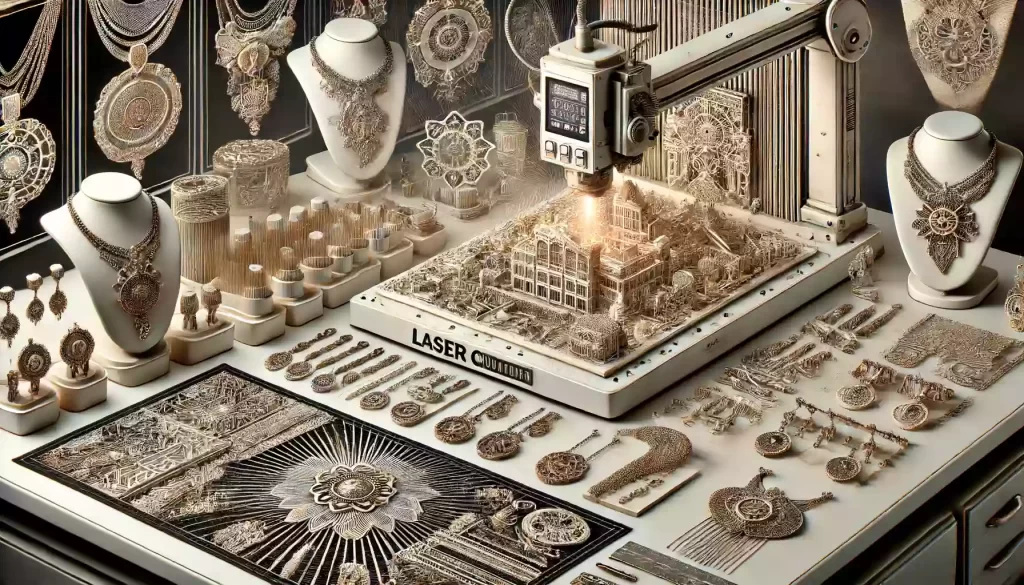

4.Processing Complex Structures:

Complex structures in jewelry, such as multi-layer pendants and intricate chains, can be precisely processed using laser cutting machines. Complex structures that are difficult to achieve with traditional methods can be easily realized through laser cutting technology, enhancing production efficiency and expanding the possibilities of jewelry design.

III. Advantages of Laser Cutting Machines

1.High Precision:

The cutting precision of laser cutting machines can reach micron levels, which is crucial in jewelry making. High precision ensures the perfection of every detail in the jewelry, making the final product more refined.

2.High Efficiency:

The high efficiency of laser cutting machines can significantly increase production speed and reduce production cycles. Compared to traditional manual cutting and engraving, laser cutting machines can complete a large number of processing tasks in a short time, boosting the productivity of jewelry making.

3.Non-Contact Processing:

Laser cutting is a non-contact processing technology that does not exert mechanical stress or damage on the material. This is especially important for precious and fragile materials like diamonds and gemstones, ensuring their integrity and luster.

4.Flexibility:

Laser cutting machines can quickly switch processing patterns and designs to meet the production needs of small batches and multiple varieties. This flexibility allows jewelry manufacturers to respond swiftly to market demands and introduce more novel and unique products.

IV. Impact of Laser Cutting Machines on the Jewelry Industry

1.Promoting Design Innovation:

The application of laser cutting technology provides jewelry designers with greater creative space. They can attempt more complex and innovative designs, thereby elevating the overall design level of the industry.

2.Reducing Production Costs:

Although the initial investment in laser cutting machines is relatively high, their high efficiency and low material wastage can significantly reduce production costs in the long run. Utilizing laser cutting technology can save a substantial amount of costs for jewelry manufacturers.

3.Enhancing Market Competitiveness:

Jewelry manufacturers using laser cutting technology can offer more exquisite and high-quality products, standing out in the highly competitive market. High-quality products not only earn customer trust but also enhance brand image and market share.

4.Meeting Personalized Needs:

The high flexibility of laser cutting machines allows jewelry manufacturers to quickly respond to personalized customer needs. Customized jewelry has become a new market trend, catering to consumers’ pursuit of unique and personalized pieces.

V. Future Development Trends

With continuous technological advancements, laser cutting technology will continue to develop in the field of jewelry. In the future, we can expect more intelligent and automated laser cutting equipment, making the jewelry making process more efficient and precise. Additionally, the combination of laser cutting technology with other advanced manufacturing technologies, such as 3D printing, will bring more innovation and possibilities to the jewelry industry.

Final Thoughts

In conclusion, the application of laser cutting machines in jewelry making has profoundly changed this traditional industry and will continue to do so. By continually introducing and applying advanced technology, jewelry manufacturers can not only improve product quality and production efficiency but also better meet market demands, driving the industry’s development and progress.