With the continuous advancement of technology, fiber laser cutter is being increasingly applied across various industries. In the electrical appliance manufacturing industry, laser cutting machines have become indispensable tools due to their efficient and precise cutting capabilities. As well as their adaptability to various materials. This article will explore in detail the applications of laser cutting machines in the electrical appliance manufacturing industry and their unique advantages.

I. Working Principle of Laser Cutting Machines

Fiber laser cutters use high-power laser beams to irradiate materials, causing the irradiated area to melt, vaporize, or ablate quickly. While high-speed airflow blows away the molten material, achieving the cutting purpose. Laser cutting is characterized by narrow cuts, high precision, and fast speed, allowing for efficient cutting of metals, plastics, ceramics, and other materials.

II. Applications of Laser Cutting Machines in the Electrical Appliance Manufacturing Industry

1.Manufacturing electrical appliance casings:

In electrical appliance manufacturing, making the casing is a crucial step. Traditional cutting methods struggle to ensure high-precision processing of complex shapes. While laser cutting machines can achieve high-precision cutting of metals, plastics, and other materials through precise control of the laser beam’s movement. This not only improves processing efficiency but also ensures the aesthetic and consistency of the casing.

2.Cutting circuit boards:

Circuit boards are core components of electrical products. Laser cutting machines can accurately cut various types of circuit boards, avoiding the damage and contamination that traditional cutting methods might cause. Additionally, laser cutting machines can quickly switch processing patterns to meet the needs of different types of circuit boards.

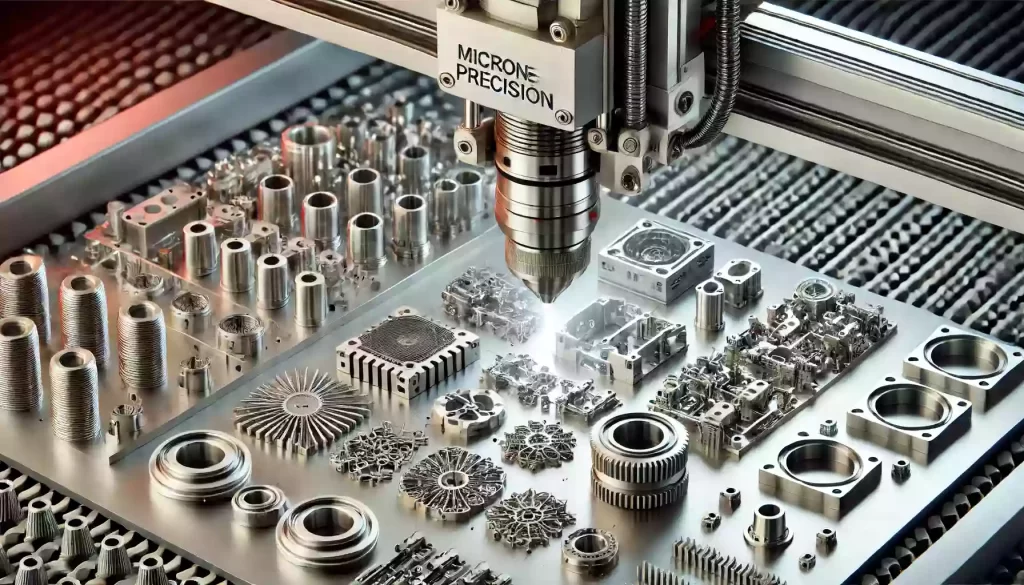

3.Processing components:

Electrical products contain many small precision components, and traditional processing methods often fail to meet the high precision and efficiency requirements. Laser cutting machines can achieve micron-level precision processing, suitable for producing various complex-shaped and high-precision components, significantly enhancing the quality and reliability of products.

III. Advantages of Laser Cutting Machines

1.High precision:

Laser cutting machines, controlled by CNC systems, can achieve high-precision cutting of complex patterns and fine structures with narrow cuts and smooth cutting surfaces, requiring little to no subsequent processing. This is particularly important for manufacturing strictly regulated electrical components and casings.

2.High efficiency:

The cutting speed of laser cutting machines is much higher than that of traditional cutting tools, significantly reducing processing time and improving production efficiency. Especially in mass production, the advantages of laser cutting machines are more pronounced, enabling continuous, high-speed automated processing.

3.Strong material adaptability:

Laser cutting machines can cut metals, plastics, ceramics, glass, and other materials, covering almost all material types required in electrical appliance manufacturing. Whether conductive or insulating materials, laser cutting machines can handle them efficiently, greatly expanding their application range.

4.High safety:

Modern laser cutting machines are designed with multiple safety protection measures, such as laser protective enclosures and automatic shutdown functions, effectively protecting the safety of operators. Additionally, the non-contact nature of laser cutting reduces the risk of mechanical wear and human error.

5.High flexibility:

Laser cutting machines, controlled by computers, can easily adjust cutting paths and parameters to meet the processing needs of different products. Particularly in prototype development and small batch production, the flexibility of laser cutting machines is crucial, allowing quick responses to market demands and shortening product development cycles.

IV. Future Prospects of Laser Cutting Machines in the Electrical Appliance Manufacturing Industry

As electrical products develop towards high performance, lightweight, and intelligence, higher requirements are placed on processing technology. Laser cutting technology, with its unique advantages, has become an important means of improving production efficiency and product quality in the electrical appliance manufacturing industry. In the future, with further advancements in laser technology, laser cutting machines will play an even greater role in the industry.

1.Intelligent development:

With the development of artificial intelligence and big data technology, laser cutting machines will deeply integrate with intelligent manufacturing systems, realizing fully automated and intelligent production processes, further improving production efficiency and product quality.

2.New material processing:

With the continuous emergence of new materials, laser cutting technology shows unique advantages in processing them. In the future, laser cutting machines will continuously expand their applications in new material fields, bringing more innovative possibilities to electrical appliance manufacturing.

3.Environmental protection and energy saving:

The laser cutting process is pollution-free and low-energy consumption, in line with the green and environmentally friendly development trend of modern manufacturing. With increasingly stringent environmental regulations, laser cutting machines will demonstrate greater potential in environmental protection and energy saving.

Final Thoughts

The extensive application of laser cutting machines in the electrical appliance manufacturing industry not only enhances production efficiency and product quality but also promotes the development of electrical products towards higher levels. With continuous technological advancement and changing market demands, laser cutting technology will undoubtedly embrace a broader development prospect, bringing new opportunities and challenges to the electrical appliance manufacturing industry.