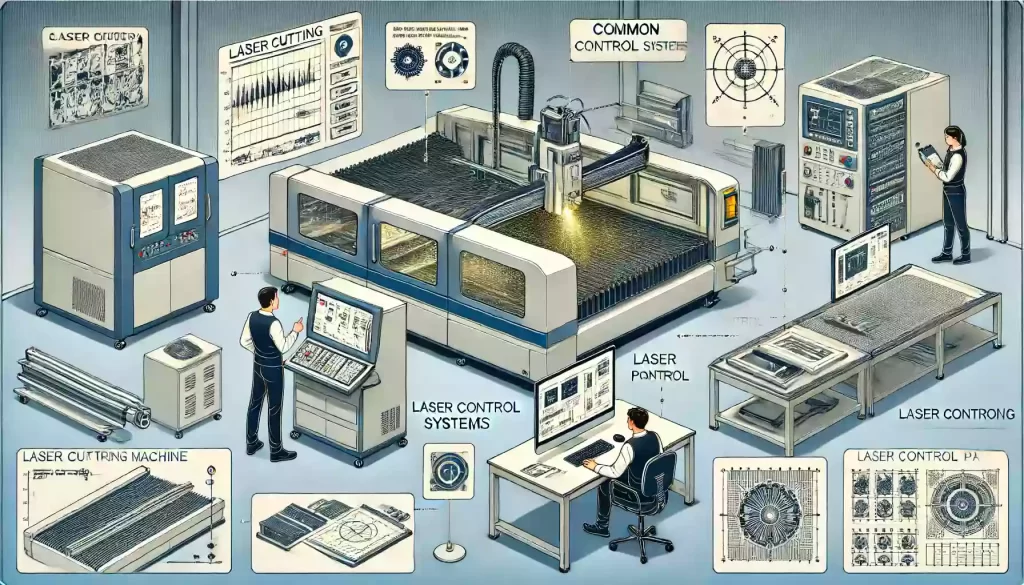

Fiber laser cutters are essential equipment in modern industrial manufacturing, widely used for precise cutting and processing of both metal and non-metal materials. The control system is the core component of a laser cutting machine, determining its cutting precision, efficiency, and stability. This article provides a detailed introduction to the common control systems for laser cutting machines, including their classification, features, main functions, and applications, supplemented with practical examples to illustrate their significance and effectiveness.

I. Classification of Laser Cutting Machine Control Systems

Fiber laser cutter control systems can be categorized based on their control methods and application areas as follows:

1. Numerical Control System (CNC):

CNC systems are the most common control systems for laser cutting machines. They achieve automatic control of the laser cutting process through pre-programmed numerical control programs. CNC systems offer high automation and precision, suitable for cutting complex patterns.

2. Laser Control System:

This control system primarily manages the laser’s start/stop, power adjustment, and optical path control. Laser control systems are typically used in conjunction with CNC systems to complete cutting tasks.

3. Image Processing System:

Image processing systems use cameras or other sensors to monitor real-time image information during the cutting process, performing automatic focusing and path adjustments to enhance cutting accuracy and quality.

4. Integrated Control System:

Integrated control systems combine CNC, laser control, image processing, and other subsystems into a single unit, providing comprehensive control over the laser cutting machine. These systems are commonly used in high-end laser cutting equipment, offering superior functionality and performance.

II. Main Functions of Laser Cutting Machine Control Systems

1. Path Control:

Control systems determine the cutting path through CNC programs or graphic files and precisely control the movement of the laser head. The precision of path control directly affects the cutting outcome, requiring high-precision servo control capabilities.

2. Power Adjustment:

Control systems adjust the laser power based on the material properties and thickness to ensure cutting quality. The accuracy and stability of power adjustment are crucial for high-quality cutting.

3. Automatic Focusing:

During the cutting process, the distance between the laser head and the material must remain consistent. Control systems achieve this through automatic focusing, continually adjusting the laser head height to maintain a constant focal distance, thereby improving cutting accuracy.

4. Automatic Nesting:

The automatic nesting function efficiently arranges multiple cutting patterns on the material, maximizing material usage and reducing waste. This function not only increases production efficiency but also lowers material costs.

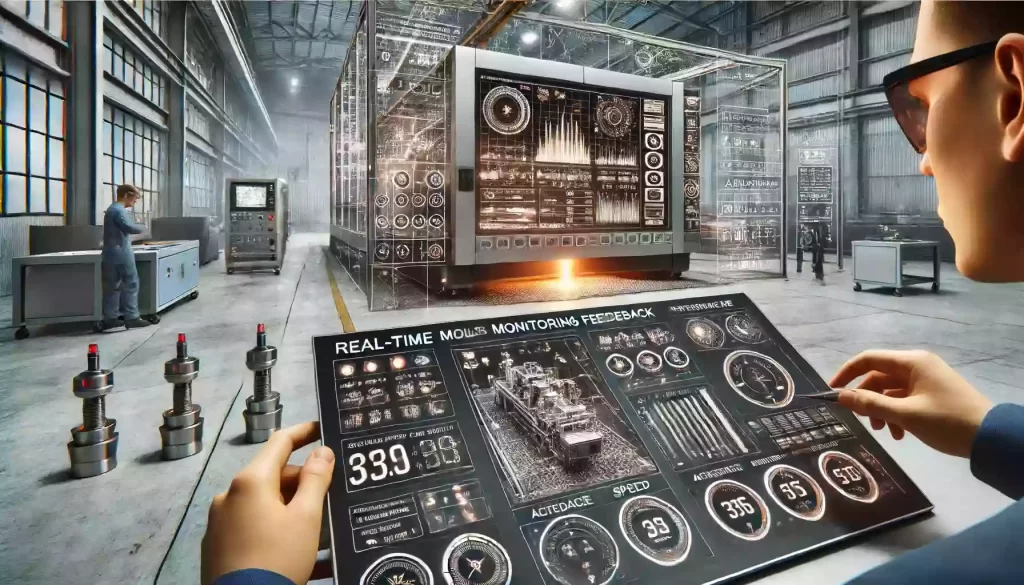

5. Real-Time Monitoring and Feedback:

Control systems use sensors to monitor various parameters such as temperature, pressure, and speed during the cutting process, providing feedback adjustments to ensure the stability and safety of the cutting process.

III. Features of Laser Cutting Machine Control Systems

1. High Precision:

Laser cutting machine control systems have high-precision motion and laser control capabilities, achieving micron-level cutting accuracy to meet high-precision processing requirements.

2. High Efficiency:

By optimizing cutting paths and automatic nesting, control systems significantly improve cutting efficiency, reducing processing time and enhancing production efficiency.

3. Stability:

Control systems ensure the stability and consistency of the cutting process through multiple monitoring and feedback mechanisms, reducing the occurrence of faults and enhancing equipment reliability.

4. Ease of Operation:

Modern laser cutting machine control systems often feature graphical user interfaces, making operation simple and intuitive, reducing the skill requirements for operators, and enhancing user convenience.

IV. Applications of Laser Cutting Machine Control Systems

Laser cutting machine control systems are widely used in various fields, including:

1. Metal Processing:

In the metal processing industry, laser cutting machine control systems are widely used for cutting materials such as stainless steel, carbon steel, and aluminum alloys. Their high precision and efficiency are suitable for cutting complex patterns and high-demand tasks.

2. Electronics Manufacturing:

The electronics manufacturing industry requires extremely high precision and speed for cutting, and laser cutting machine control systems excel in these aspects, widely used for precise cutting of circuit boards and electronic components.

3. Aerospace:

The aerospace industry has stringent requirements for material processing, and the high precision and stability of laser cutting machine control systems meet the precision manufacturing needs of aerospace components.

4. Automotive Manufacturing:

In the automotive manufacturing field, laser cutting machine control systems are widely used for cutting body, chassis, and engine components. Their high efficiency and quality significantly enhance production efficiency and product quality.

Final Thoughts

As the core part of laser cutting equipment, laser cutting machine control systems determine the cutting performance and operational efficiency of the equipment. Through continuous technological innovation and optimization, modern laser cutting machine control systems offer high precision, high efficiency, stability, and ease of operation, widely applied in various fields, significantly enhancing industrial manufacturing levels and efficiency. Mastering the principles and usage methods of laser cutting machine control systems is crucial for improving production efficiency and product quality. This article aims to provide insights into the understanding and use of laser cutting machine control systems.